High Technology Projects

I became interested in high technology in high school. I started reading about electronics and mechanics, and shortly after that I started designing 3d models and drawing electric circuits. Buying my first 3d printer opened a new world of opportunities for me. This is when I got into rapid prototyping. With this technology, I can test my ideas quickly and at a very low cost.

Over time, I’ve evolved from a self-taught enthusiast into a passionate innovator, constantly challenging conventions and pushing boundaries to develop effective and inventive solutions.

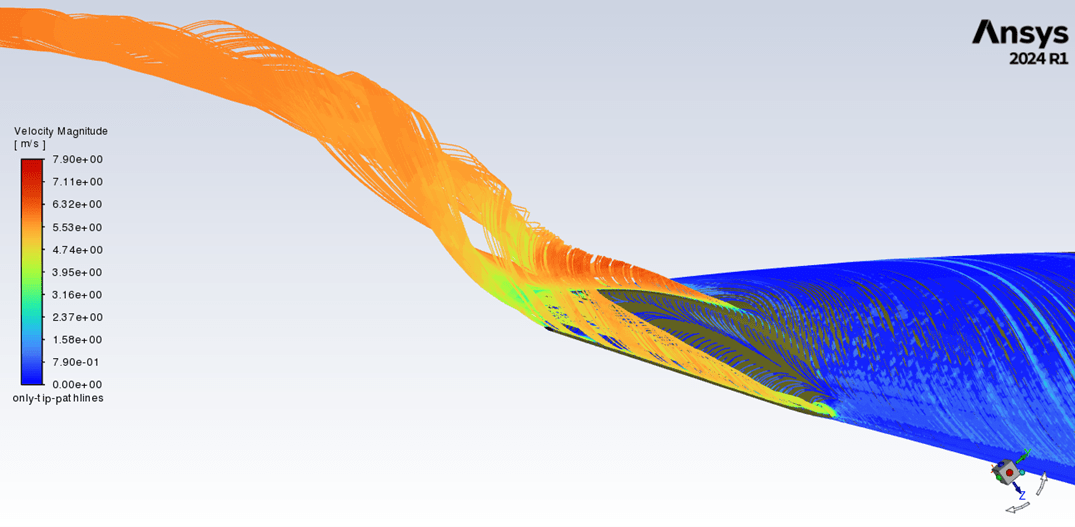

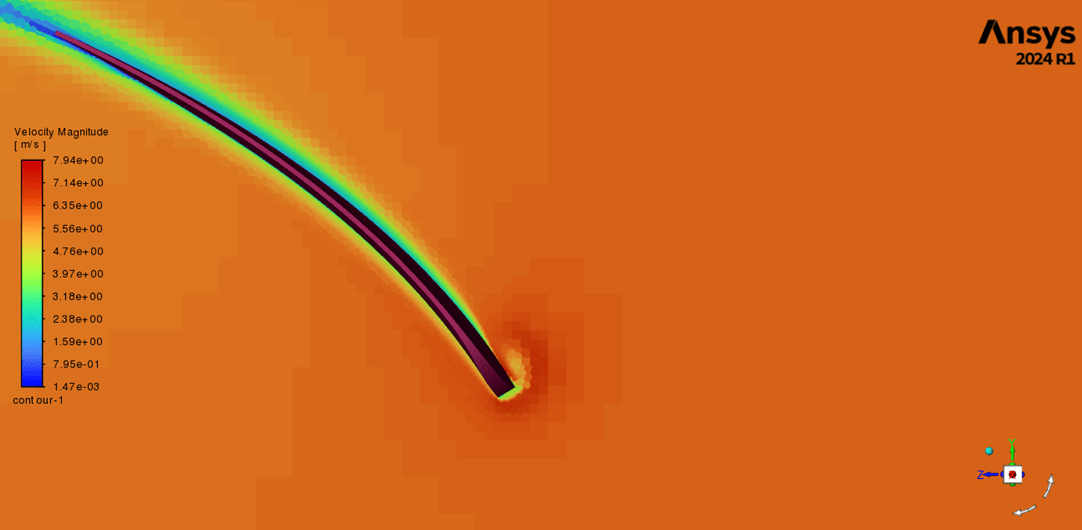

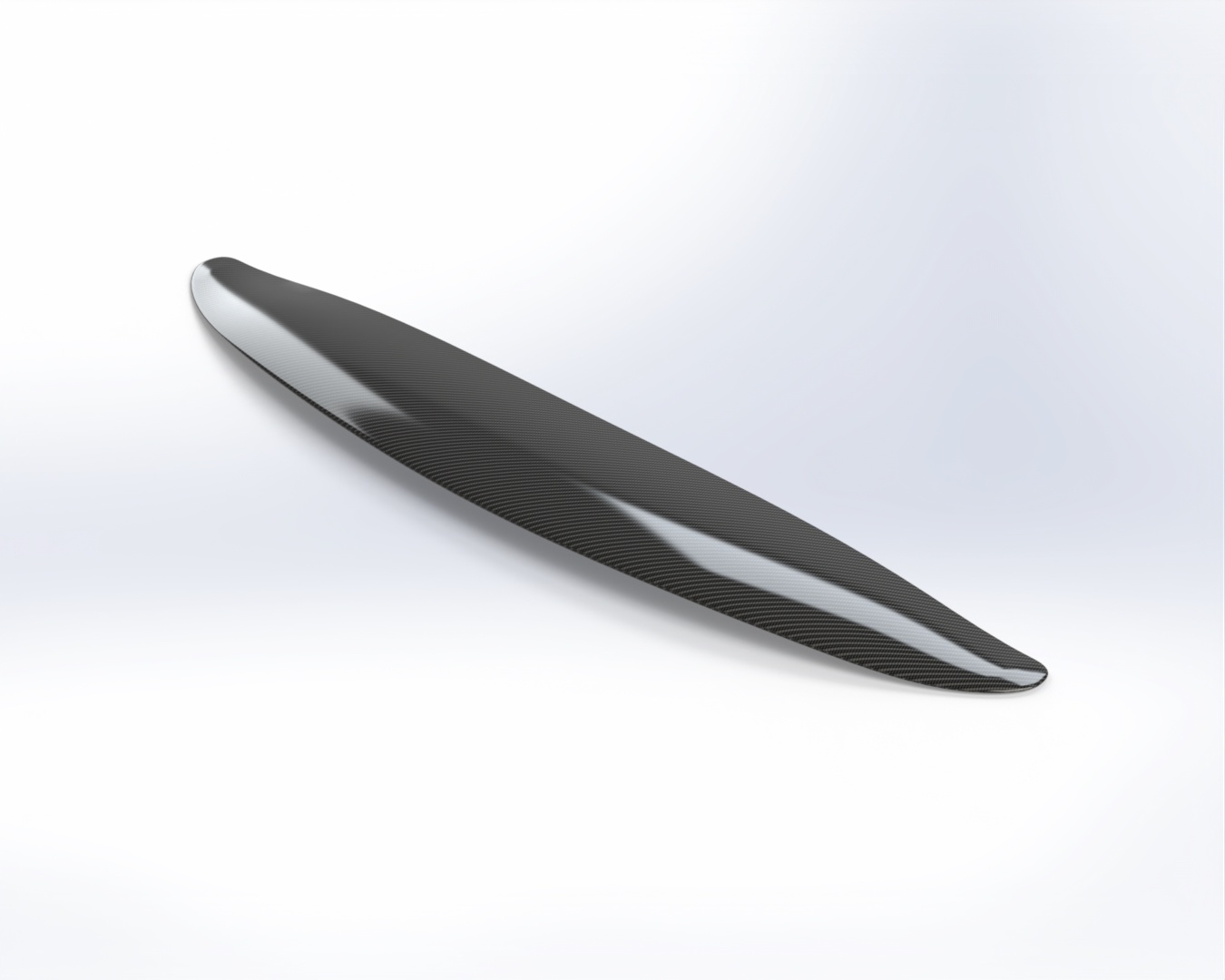

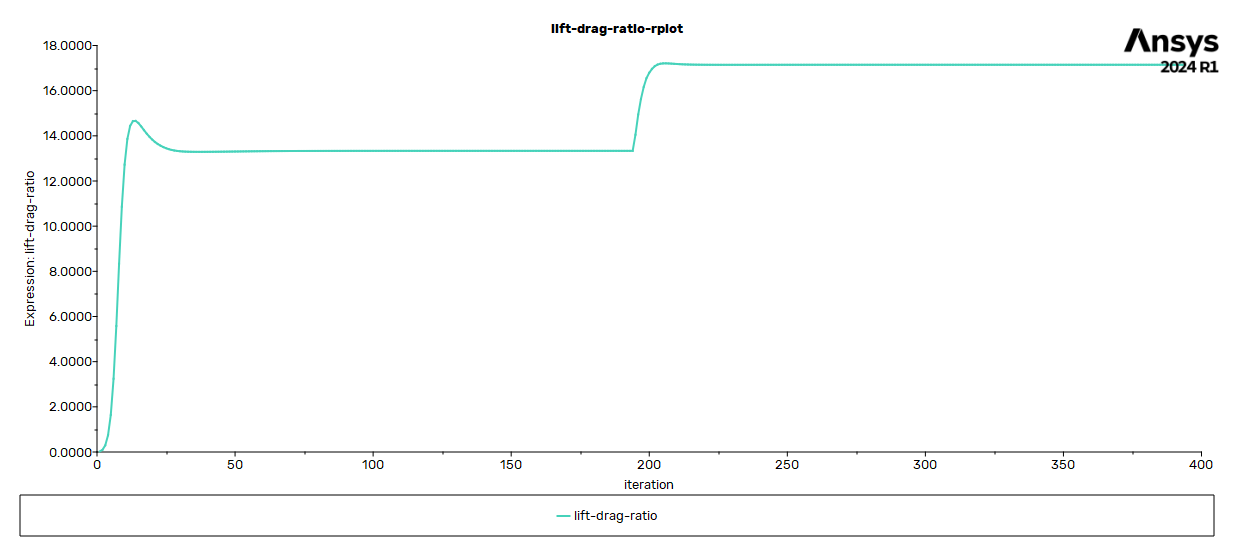

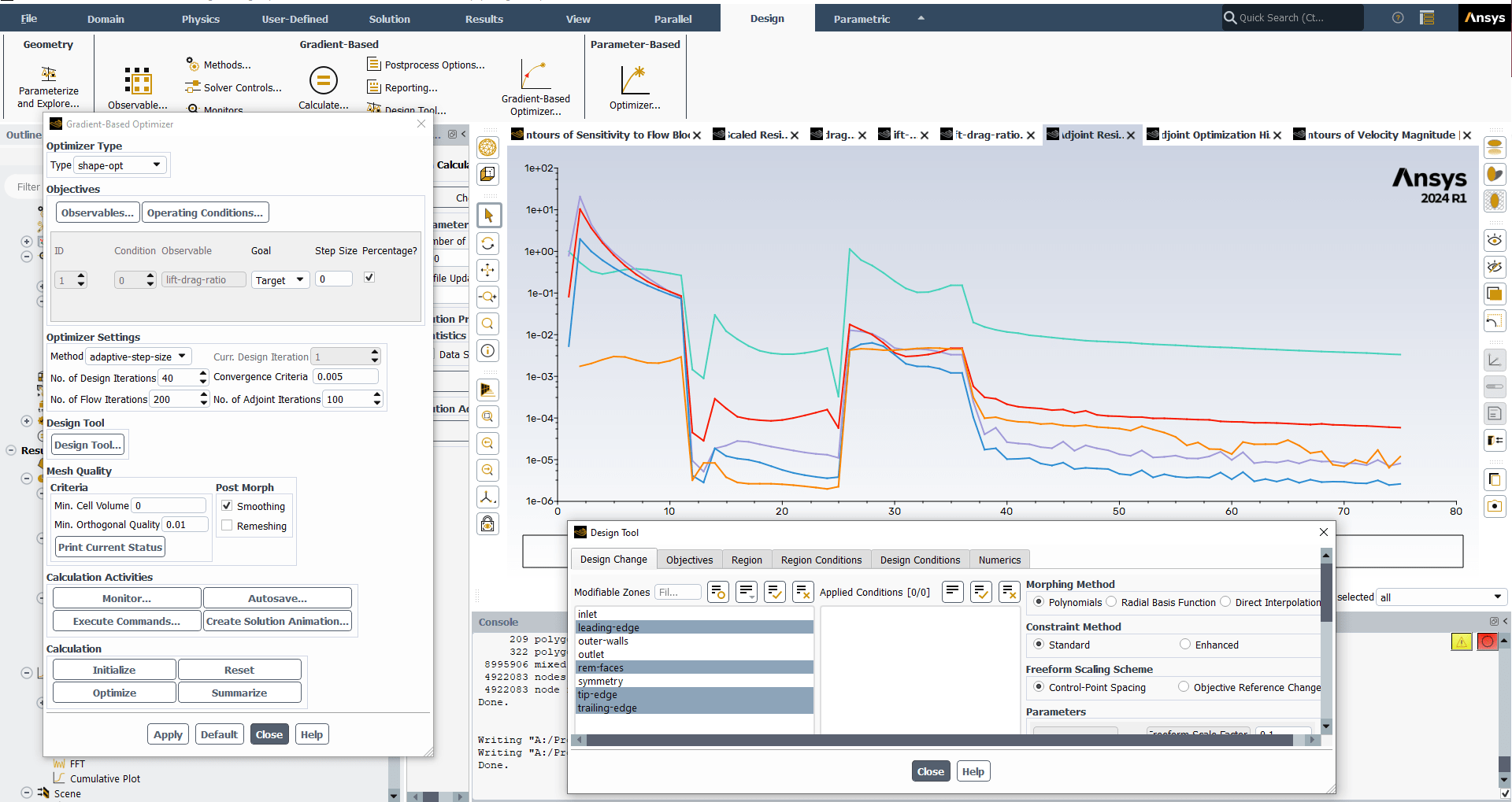

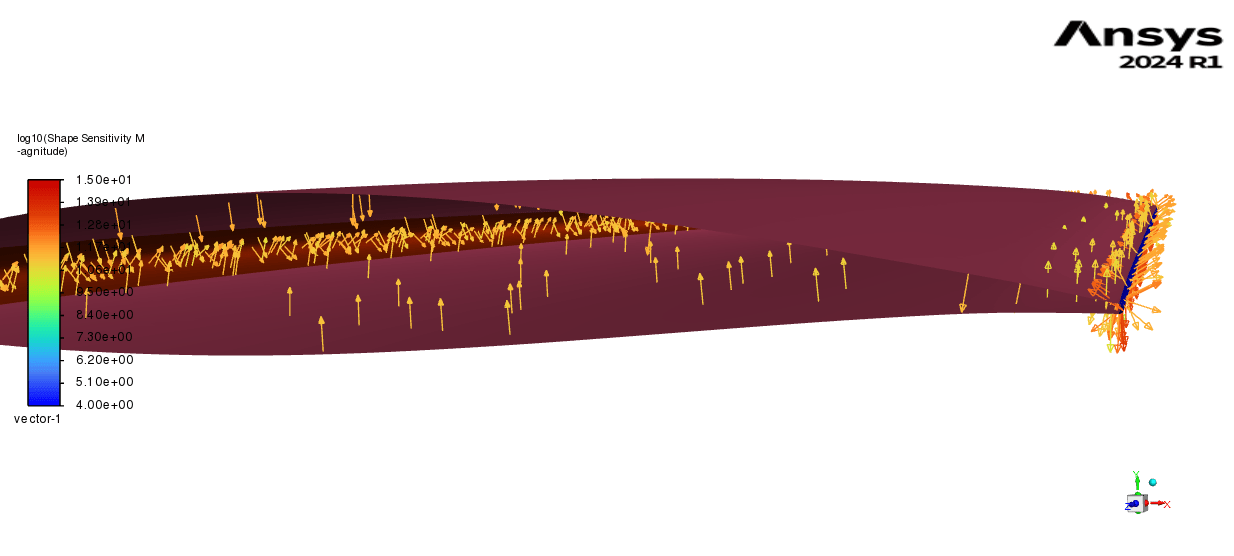

Hydrodynamic Optimization

While working on optimization projects in hydrofoil domain, I utilize Ansys Fluent software to perform CFD analysis, incorporating built-in features like the Adjoint Solver to accelerate the optimization process and identify optimal design features based on specific criteria. Additionally, I conduct hydrotunnel testing to validate and refine new designs, ensuring practical effectiveness and reliability.

Urban Wind Behavior - CFD

o evaluate the potential for natural ventilation and mitigate the urban heat island effect in Wroclaw, I conducted a comprehensive simulation of wind patterns using Ansys Fluent. By performing turbulent flow analysis, this study enables architects and urban planners to optimize building designs, improve urban layouts for enhanced ventilation, and strategically plan public spaces such as playgrounds to reduce citizens’ exposure to excessive heat.

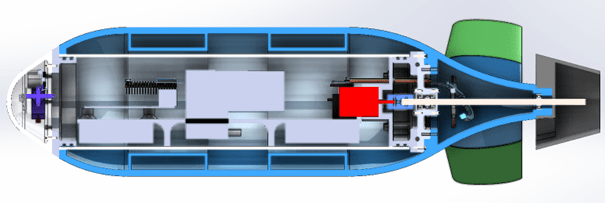

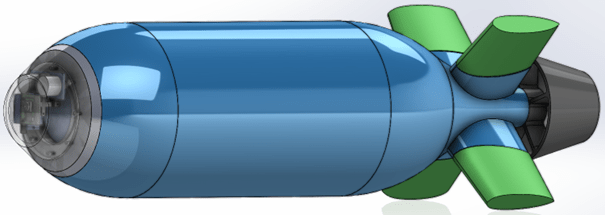

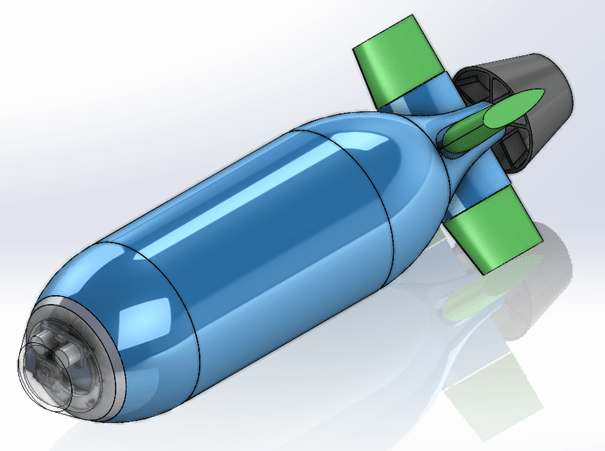

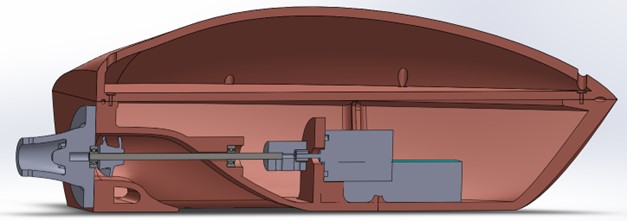

Underwater Research Vehicle

As part of my engineering thesis, I developed an underwater vehicle designed for research and exploration purposes. Driven by a fascination with the largely unexplored underwater world, I sought to build a tool capable of assisting in both scientific discovery and search and rescue operations. Its sensing capabilities, ease of use, and compact size enhance its effectiveness for these purposes. Throughout this project, I gained extensive knowledge in hydrodynamics, stress calculations, and GD&T rules, all of which were crucial for ensuring the vehicle’s waterproof integrity and operational efficiency.

You can read my engineering thesis, which includes project details and photos here.

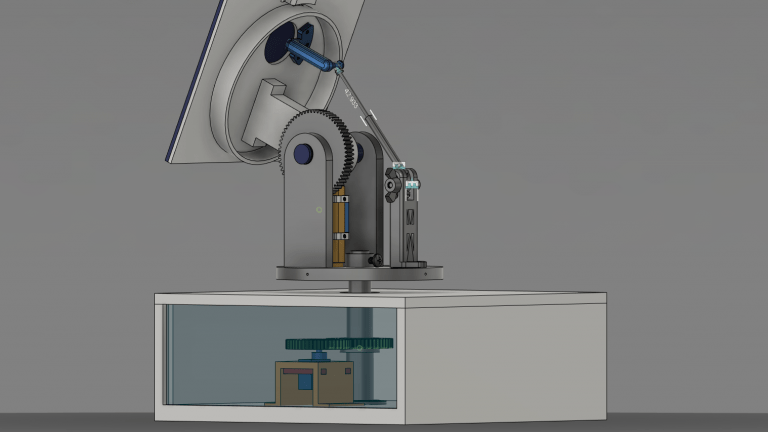

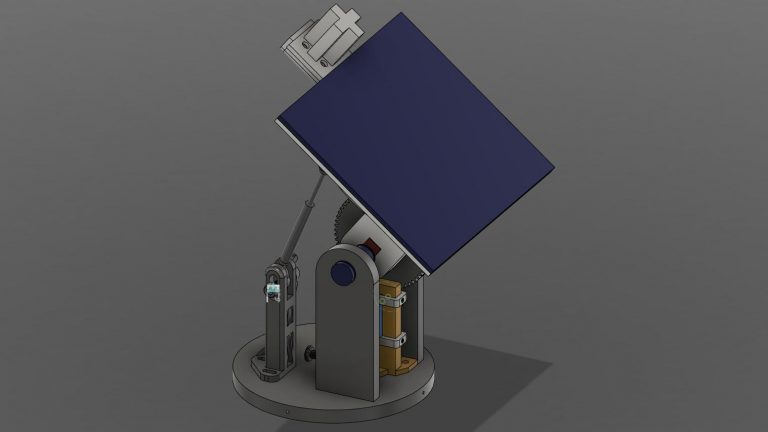

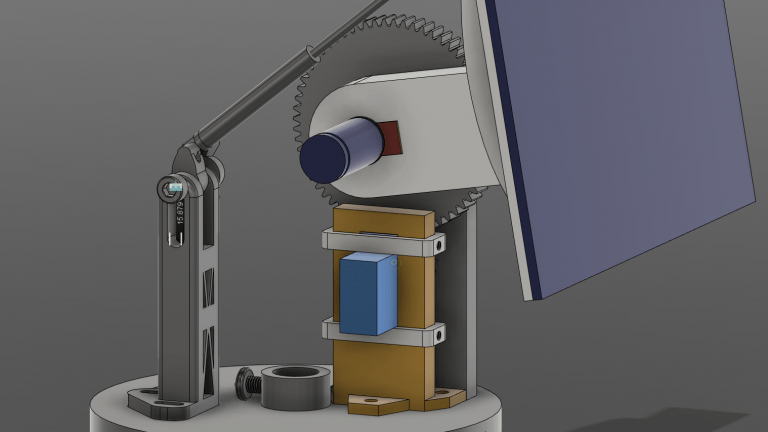

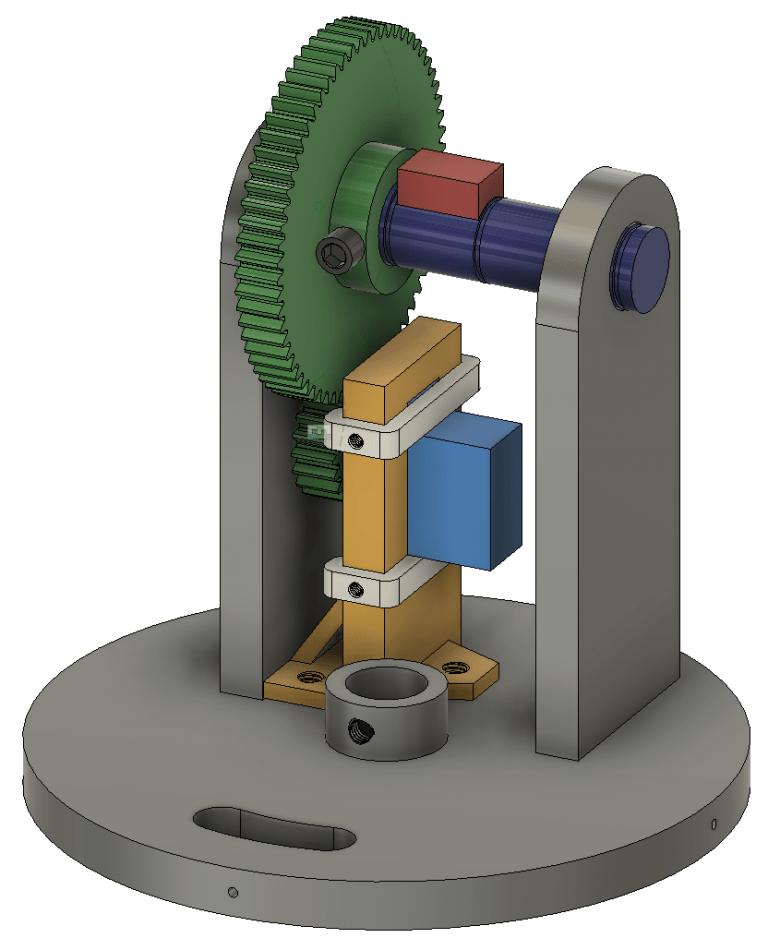

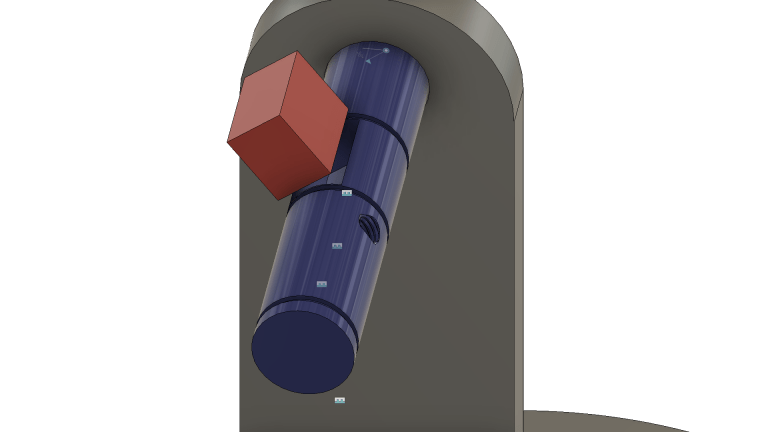

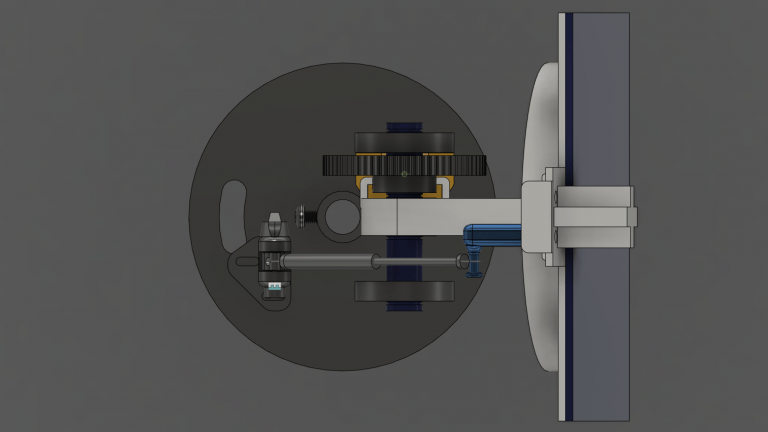

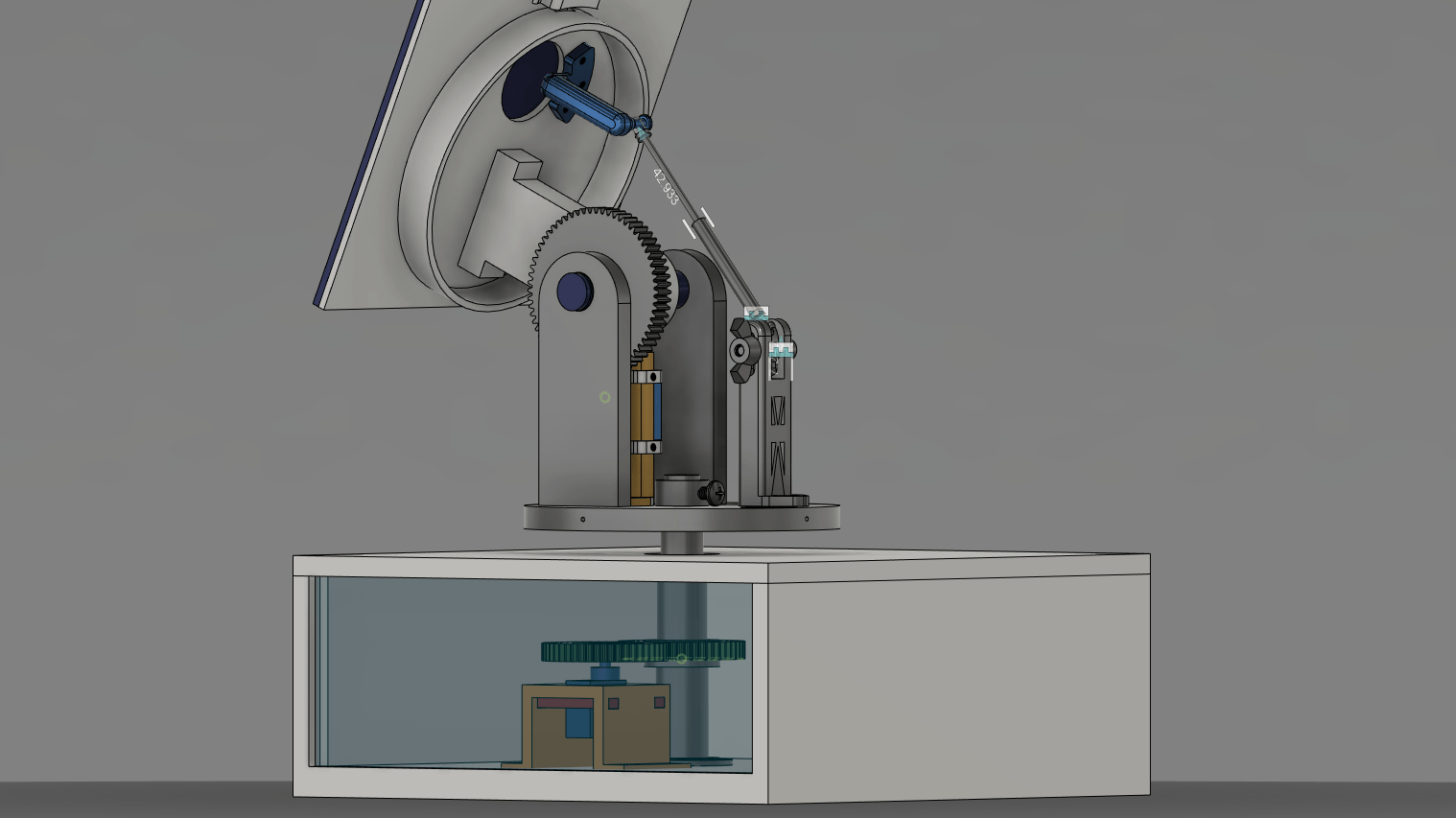

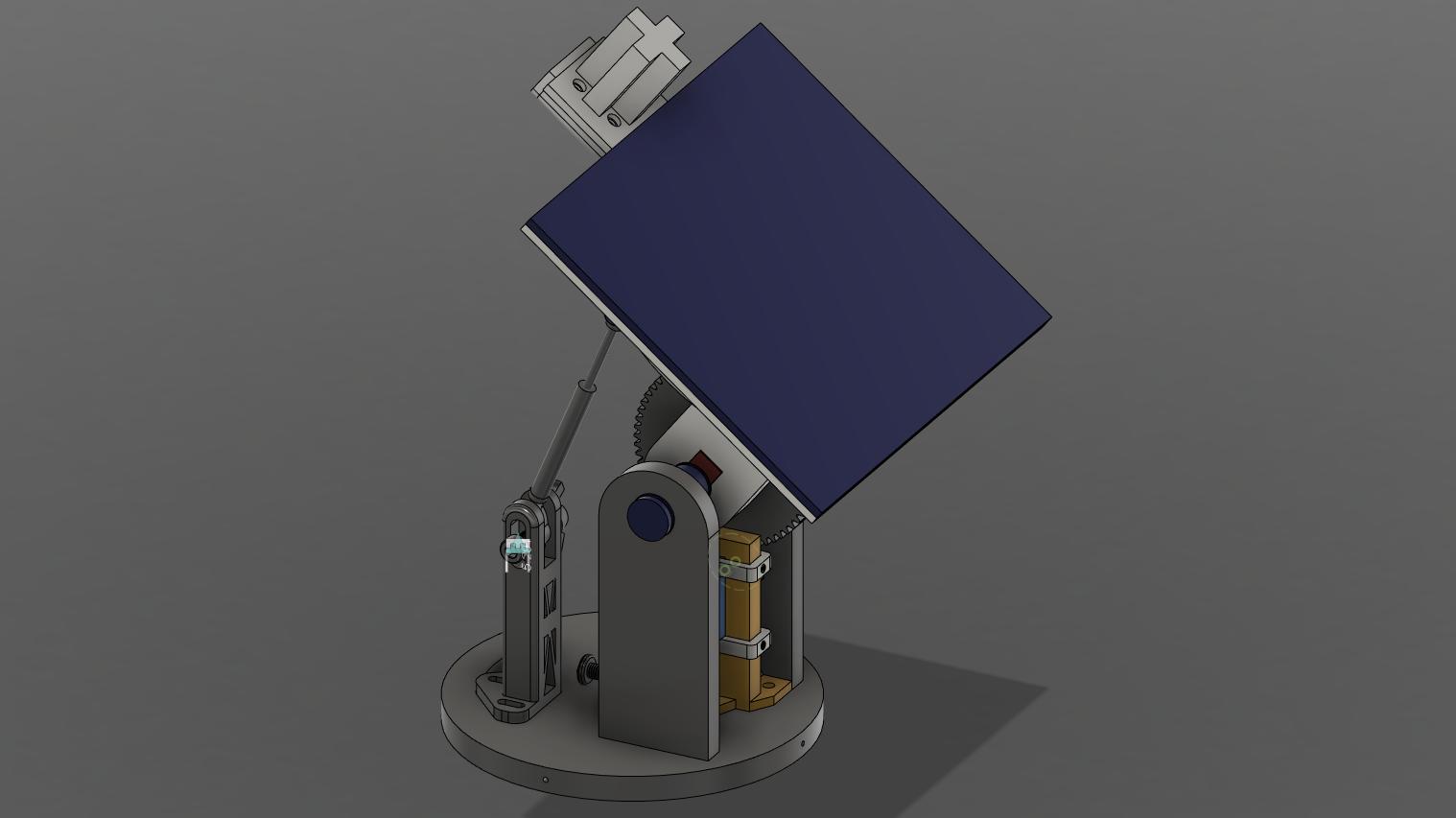

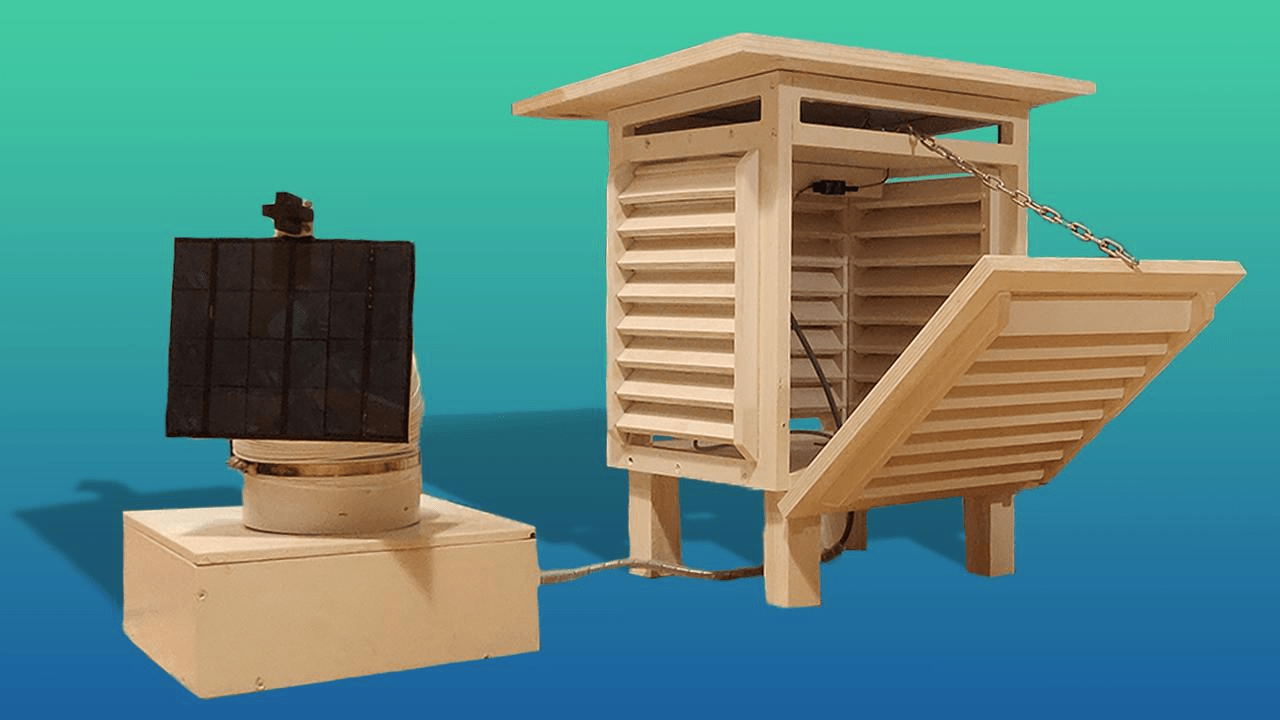

Solar Tracker

In 2018 I came up with the idea of a device that will be able to evaluate the profitability of a solar power system in residential places. I knew that there were solar maps available and these maps could give a clue about the effectiveness of a solar power system. But those maps were made for sparsely-populated areas and they weren’t so accurate in accounting for the changes in the moderizing landscapes of our cities.

I dedicated nearly two years to this project, marking my debut as a serious engineer. It was a fantastic journey that allowed me to delve deeply into electronics, mechanics, programming, and 3D design, and it became a pivotal learning experience in my engineering career.

In 2019, I entered the solar tracker in the Polish National Olympiad of Technical Innovation and Invention in Warsaw. This Olympiad is a technical contest where young people present their inventions in 3 stages: local, county, and national. Placing second at the national level gave me a free pass to all of the best technical universities in Poland and gave me the confidence to continue inventing.

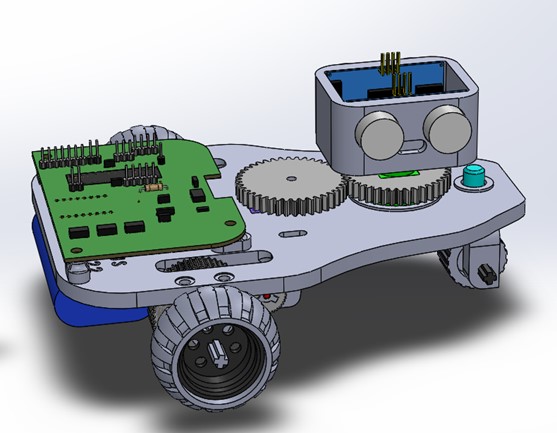

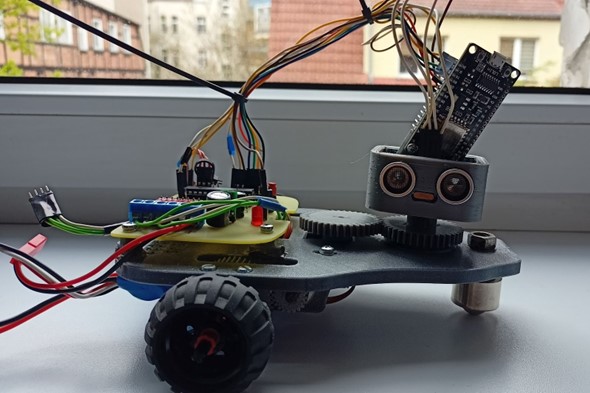

Ultrasonic Mapping Robot

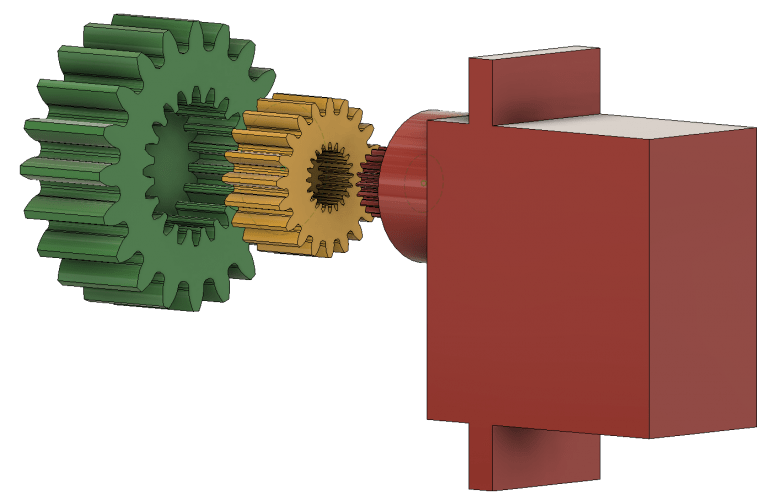

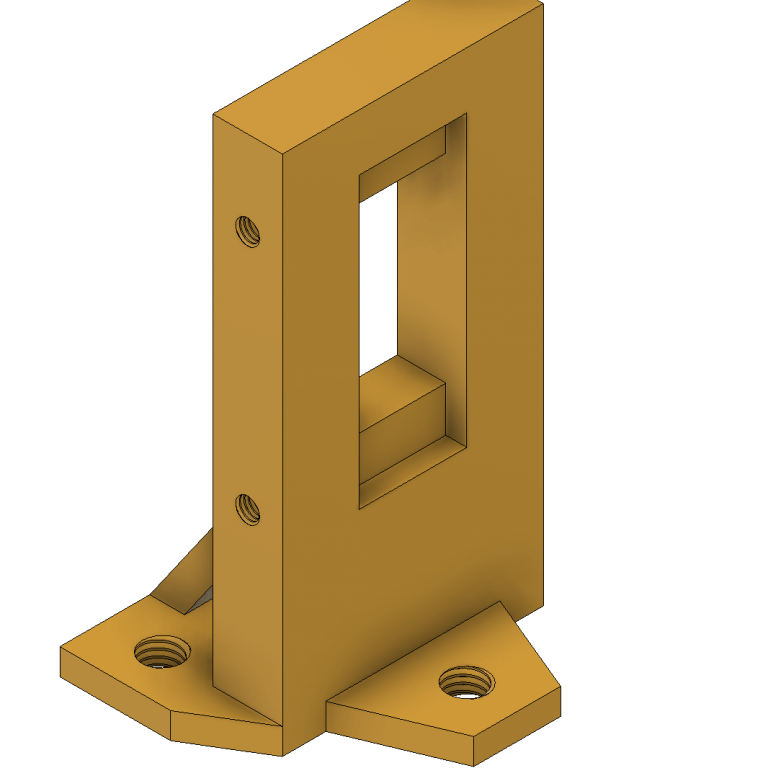

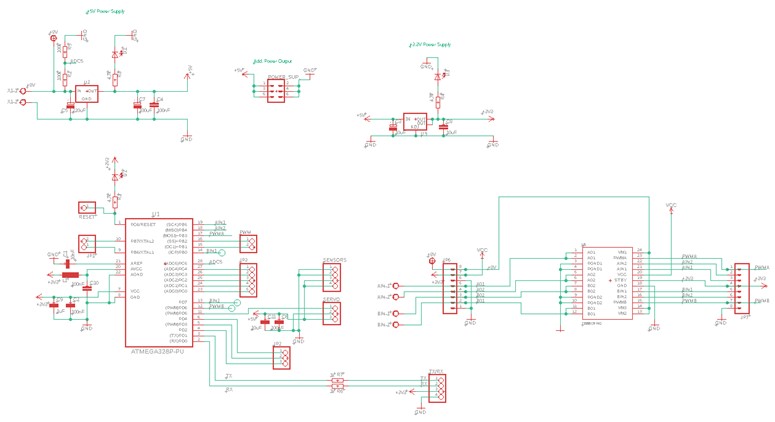

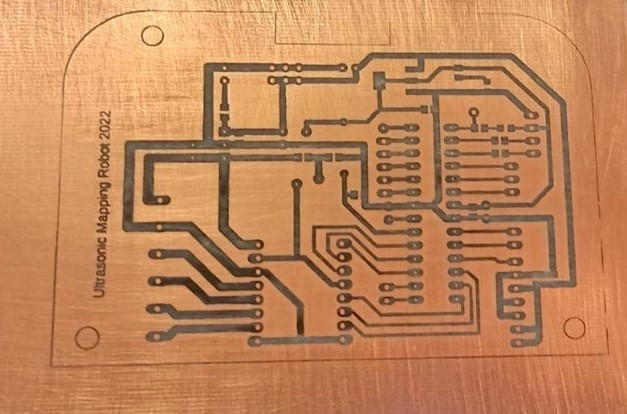

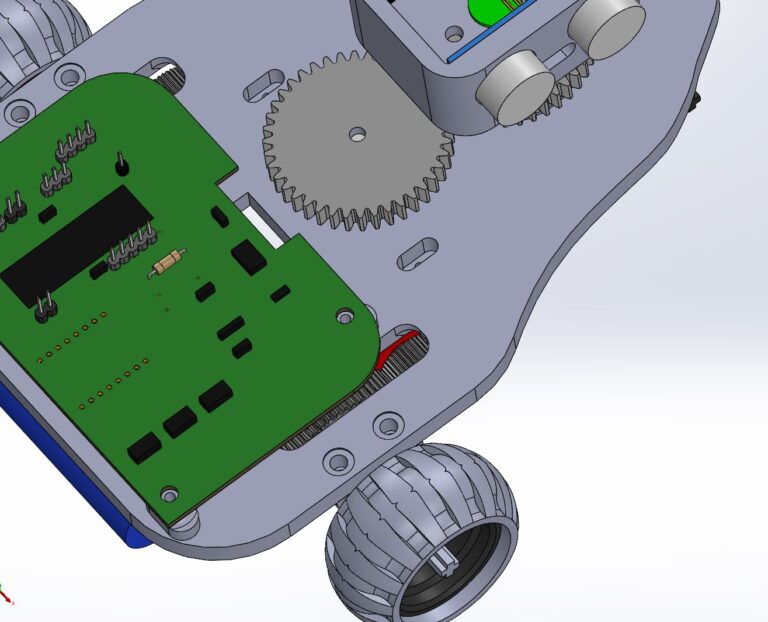

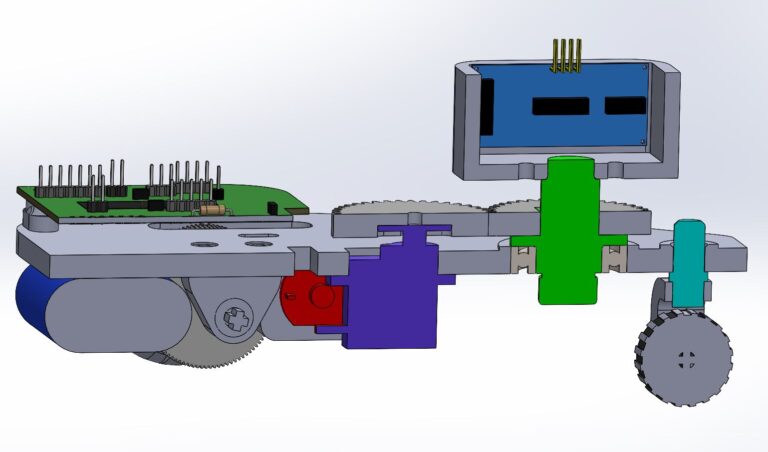

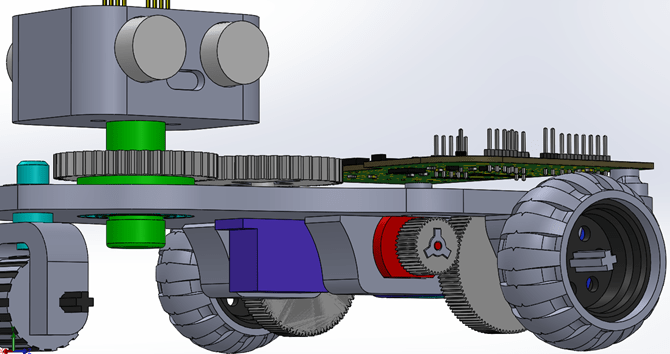

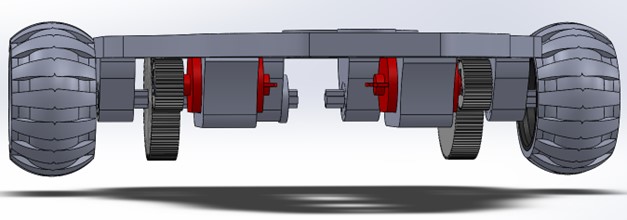

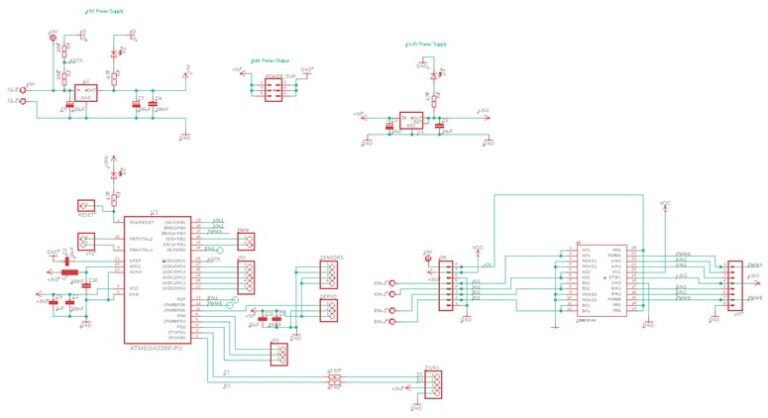

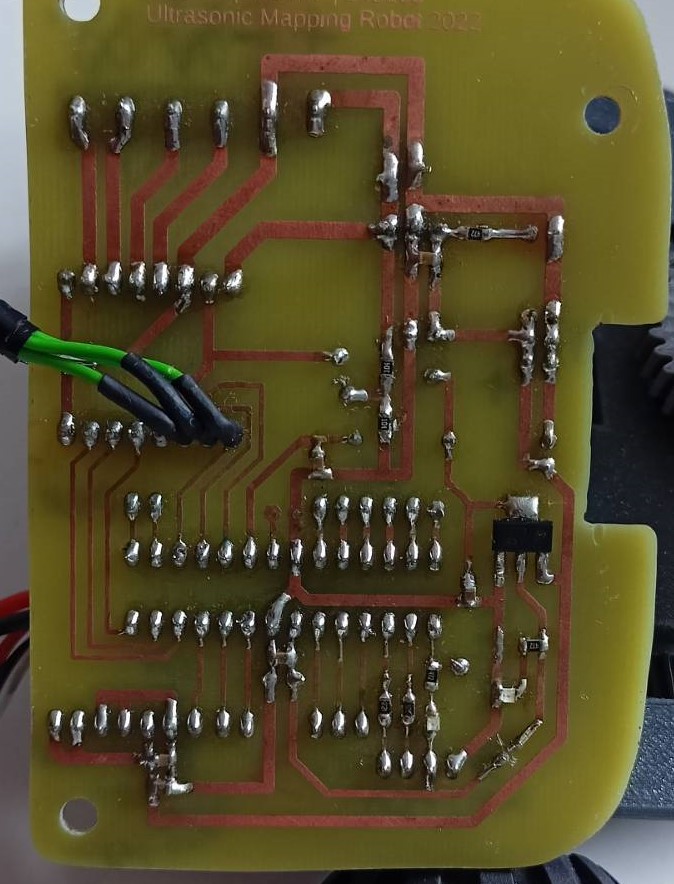

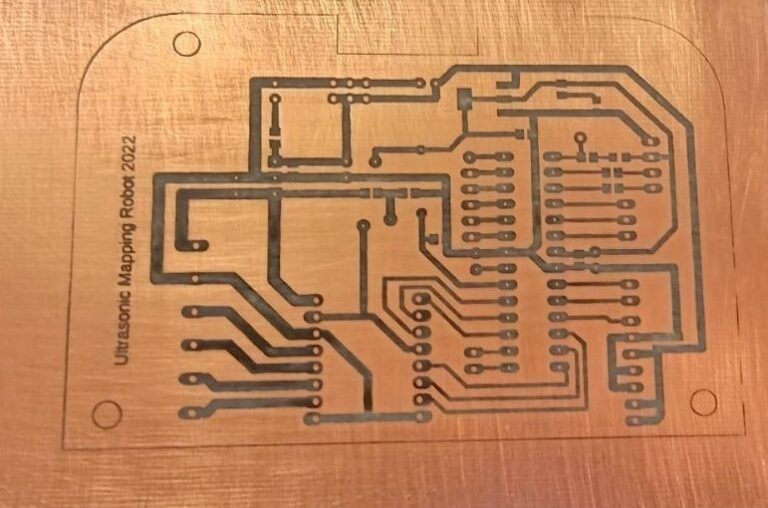

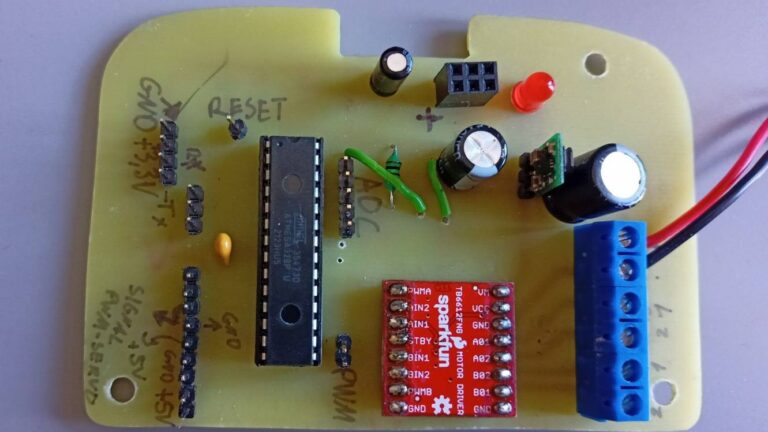

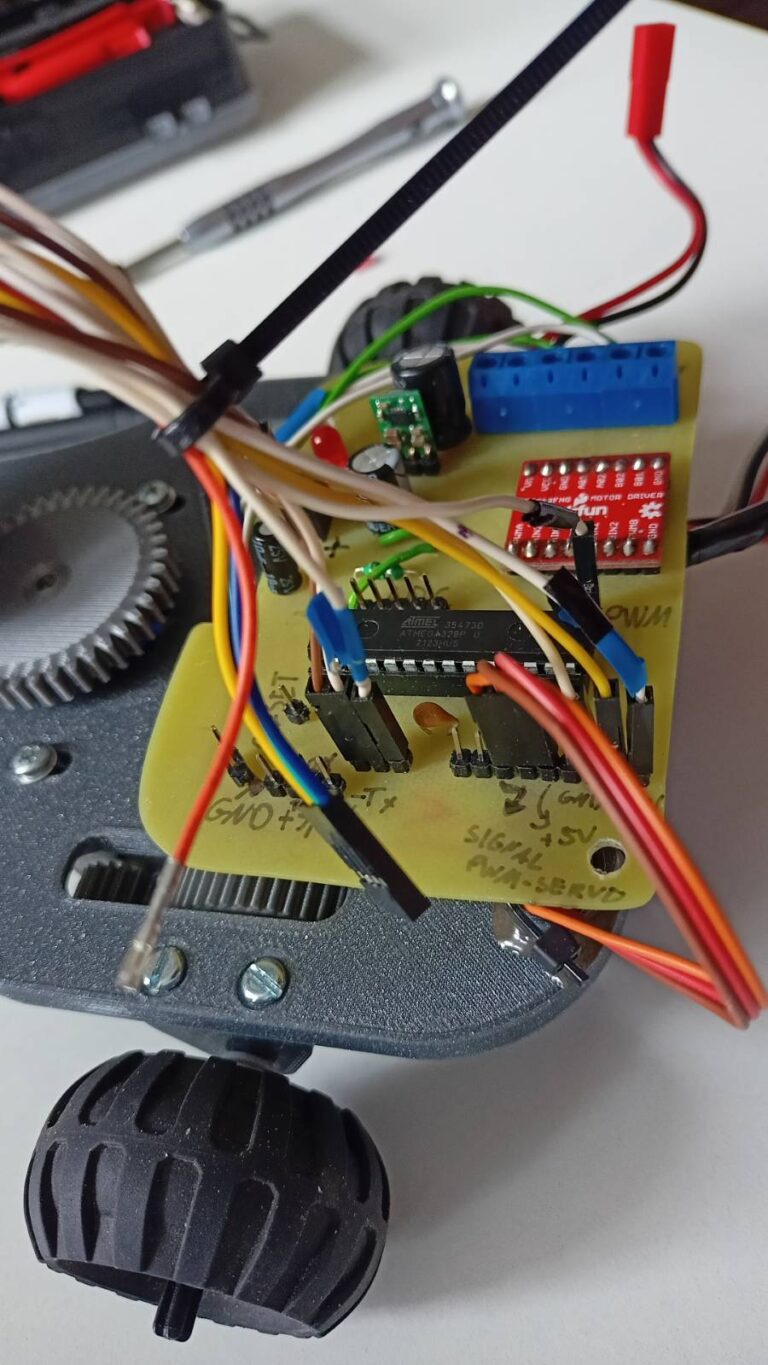

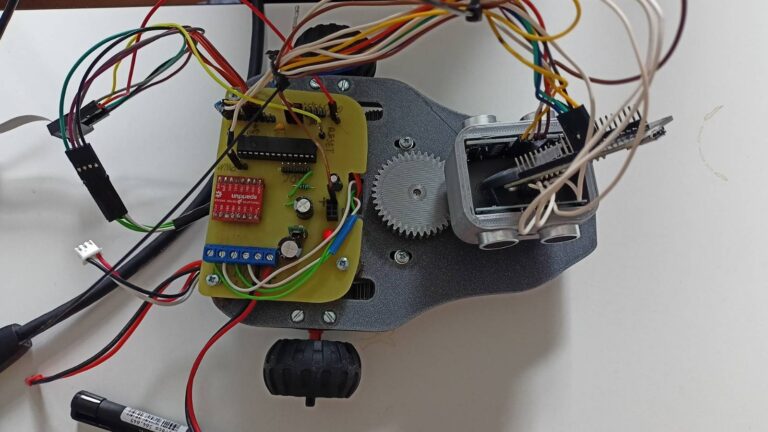

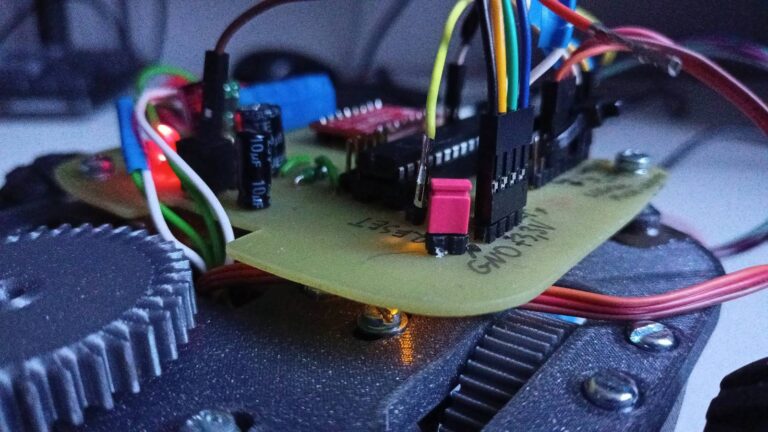

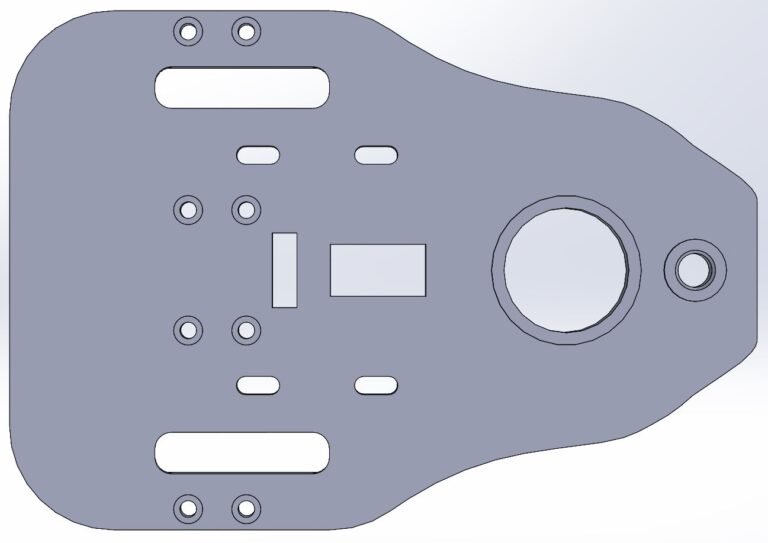

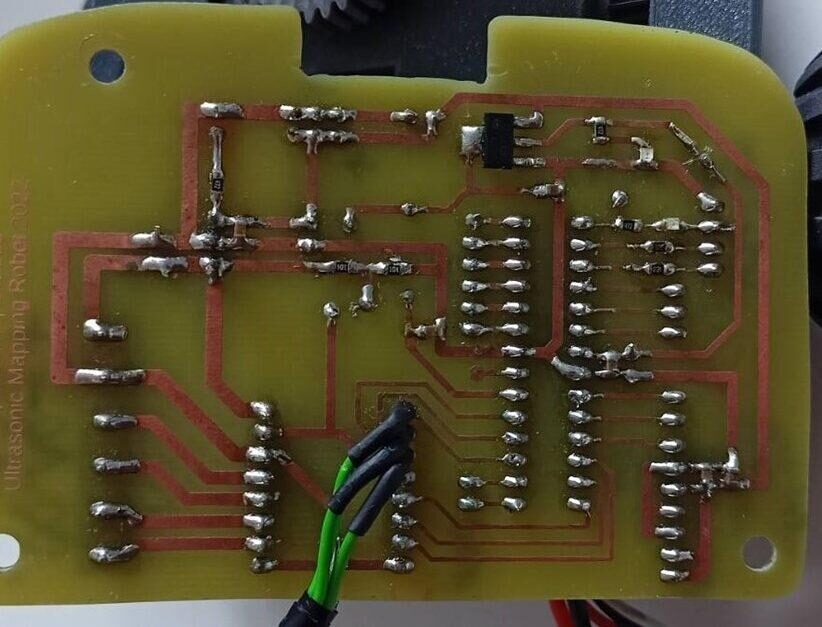

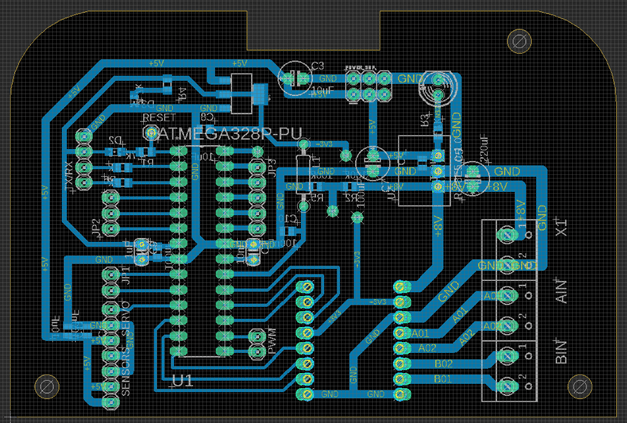

In 2022 I started working on a new device that would be able to scan the area around it, make a 2D map of the surrounding, detect obstacles and autonomously move around and find the optimal path to the destination. I used SOLIDWORKS to make 3d models, Autodesk Eagle to create electric circuit and PCB deisgn, Fusion 360 to integrate with Eagle, and Cura slicer to print all the parts on my 3d printer.

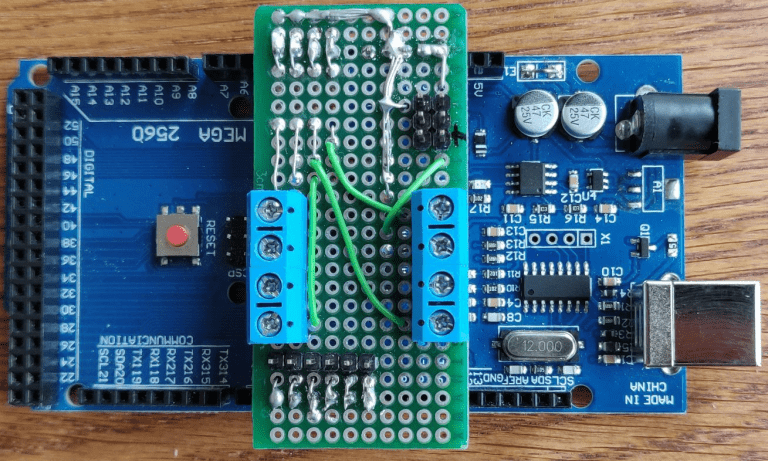

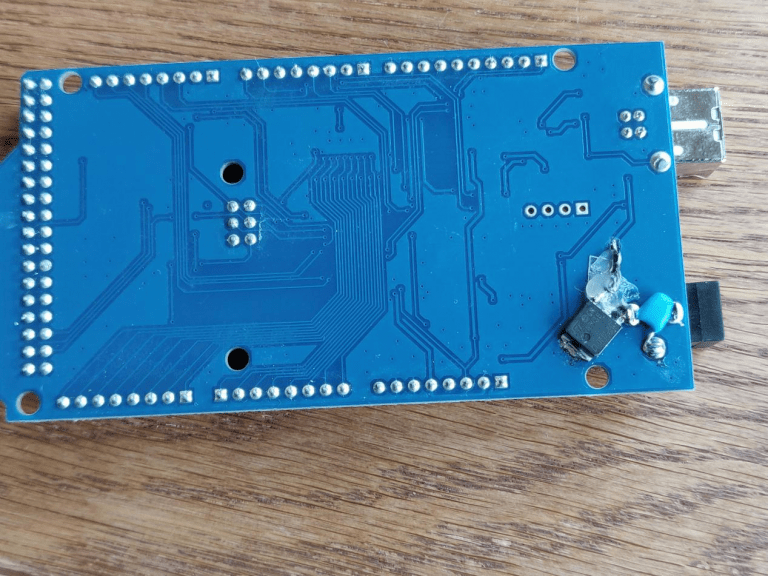

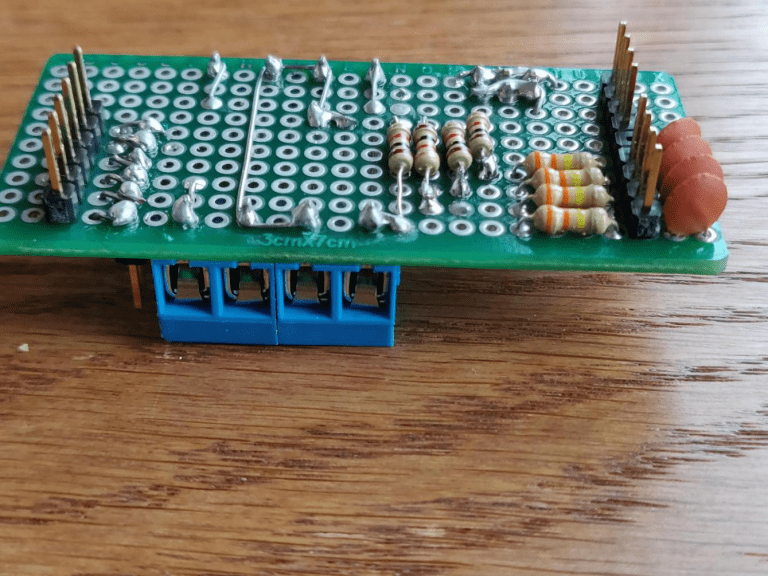

I built this project using: two DC motors I found in old toys, one servo motor to rotate a turret, two ultrasonic distance sensors to detect objects and create digital maps of the surrounding, microcontroller AVR – Atmega 328 (coded in Assembler) and WiFi ESP8266 + NodeMCU v3 module. In addition to that, all the gears, mounts, and chassis was 3d printed. All the electronics were soldered onto the custom-made PCB that I etched at home.

To see more details click here.

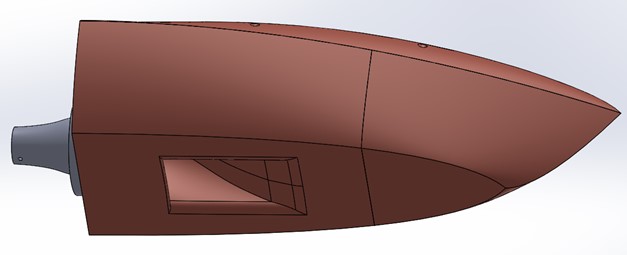

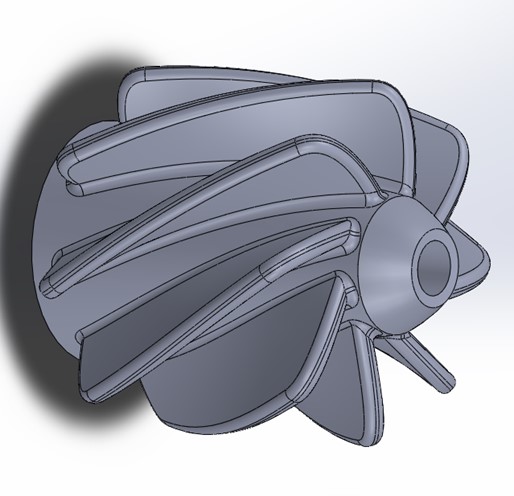

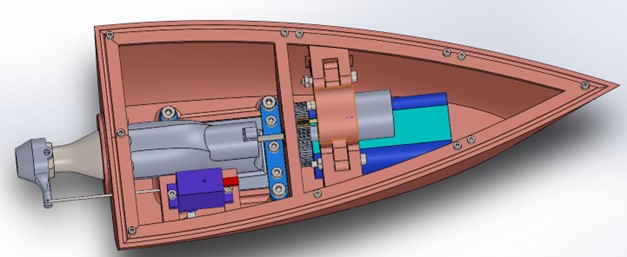

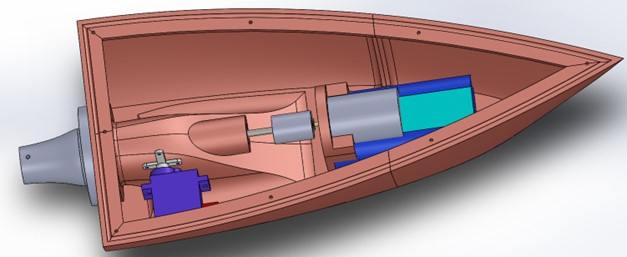

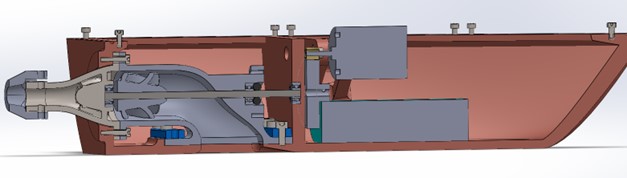

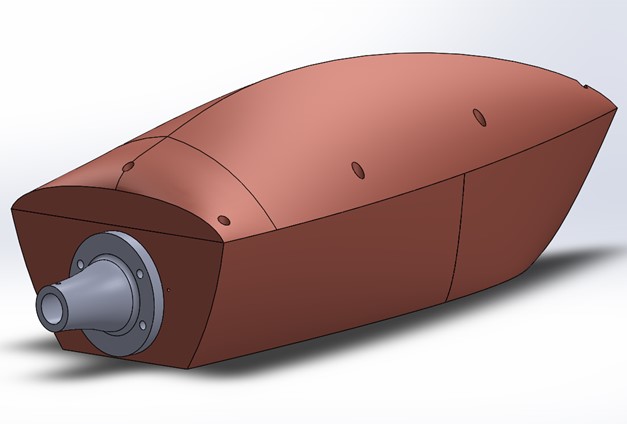

Jet Boat

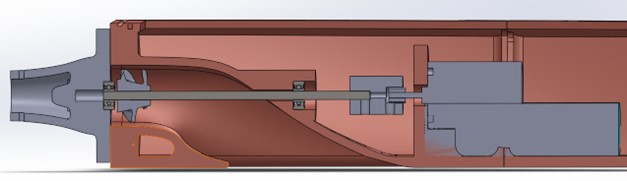

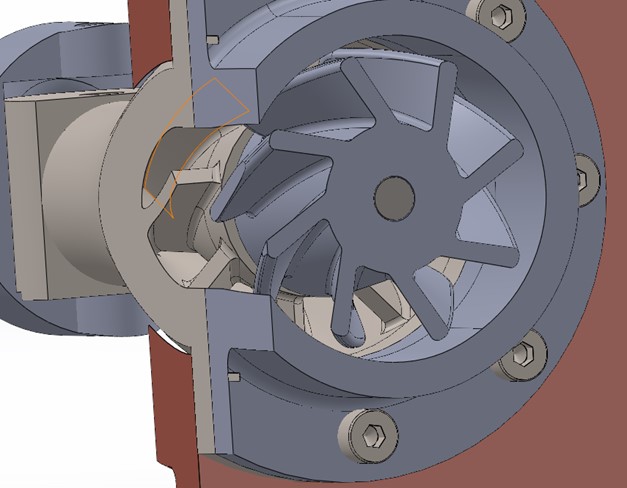

After completing a few successful projects, I decided to move to a higher level of engineering which is building something that can move on water. It’s a different level, because such an object has to be waterproof, hydrodynamic, and thus carefully designed.

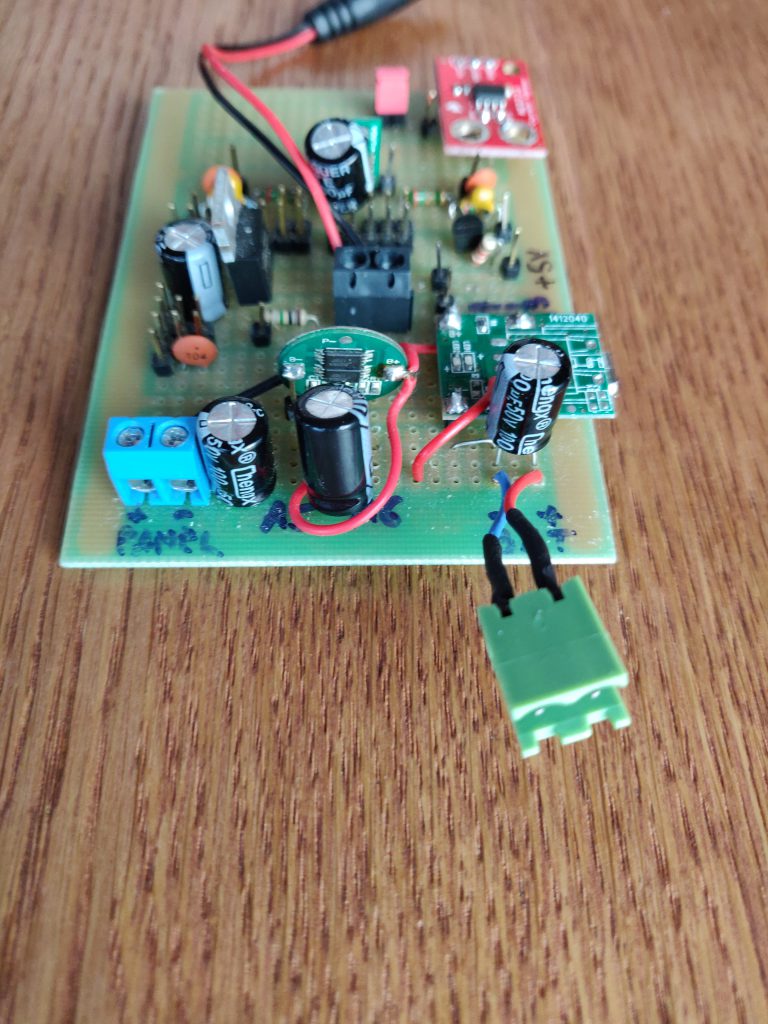

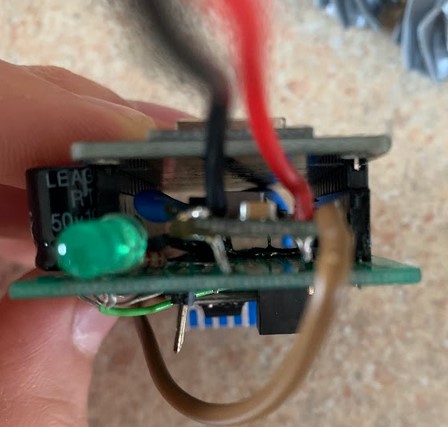

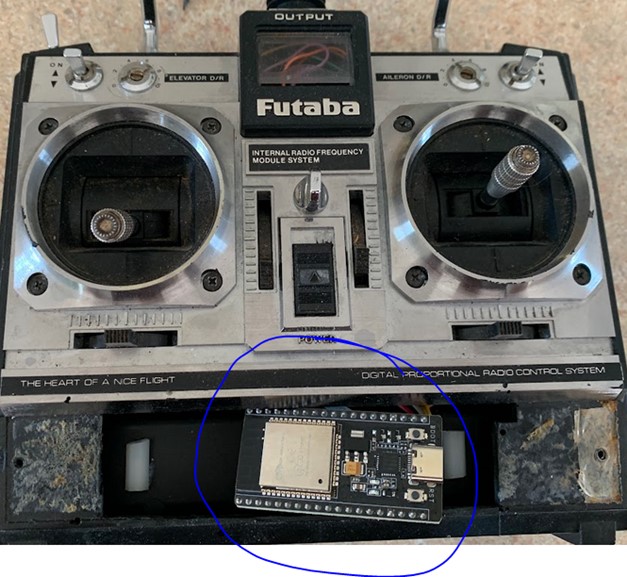

I decided to build a boat with a water jet engine, which sucks water from beneath the hull and uses special propellers to extract water with great force behind the boat. To control the boat I decided to upgrade my old RC controller with brand new ESP32 microcontroller, newly designed custom PCB, and custom-written software that is capable of achieving high-speed connection up to 100 meters.

So far, I’ve been able to build two iterations of this boat, with a few different jet engine designs, different materials and better software.

You can find detailed description and technical documentation of this project here.

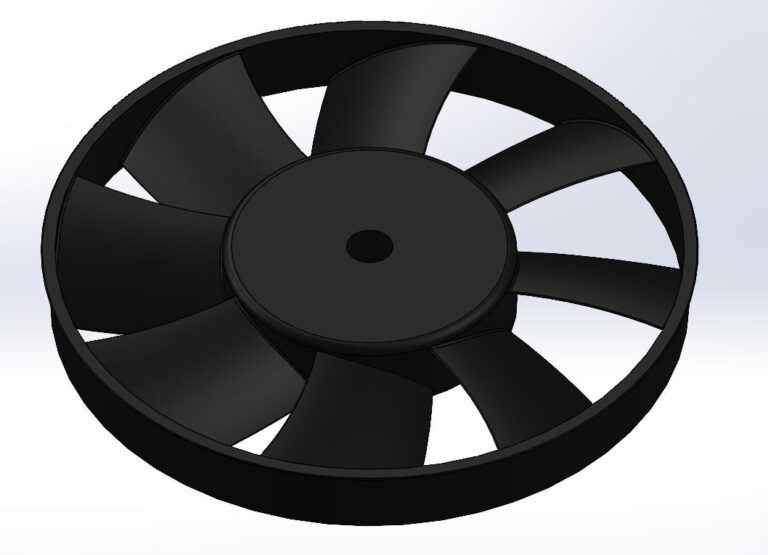

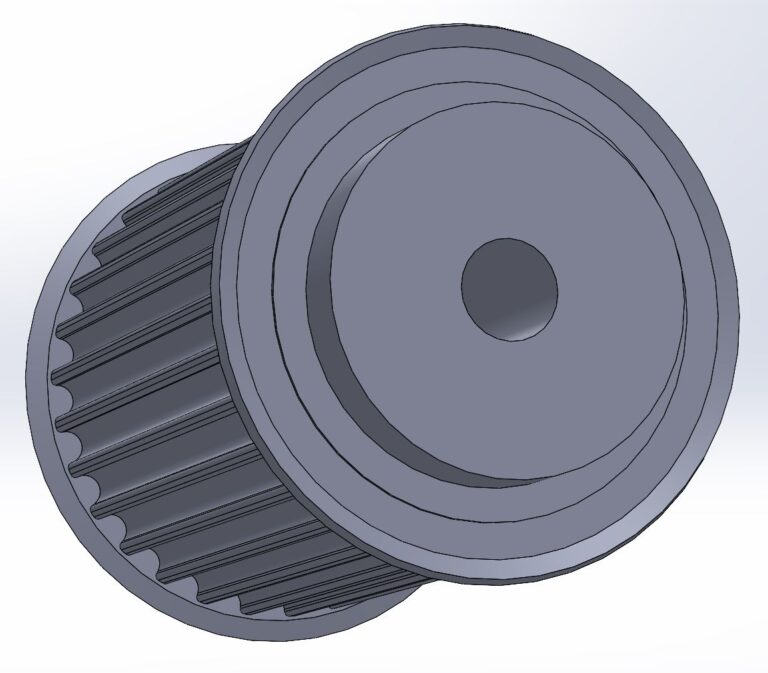

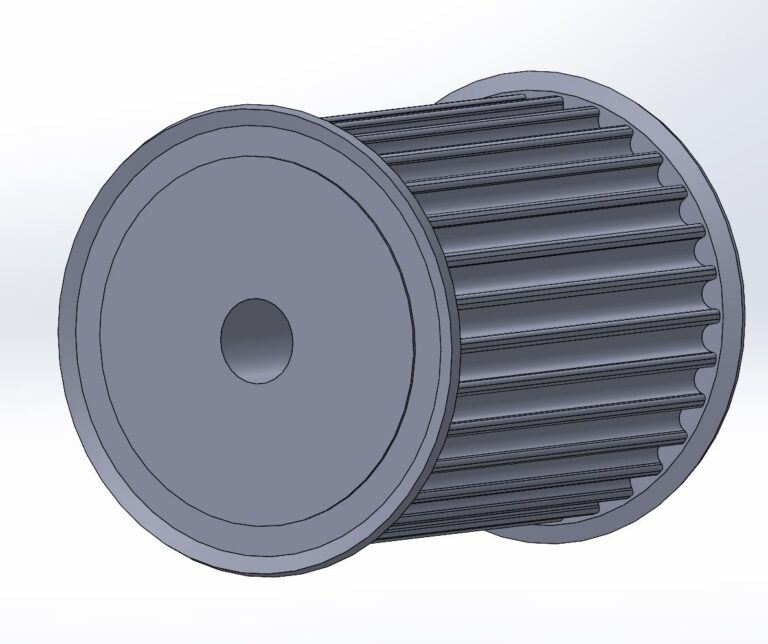

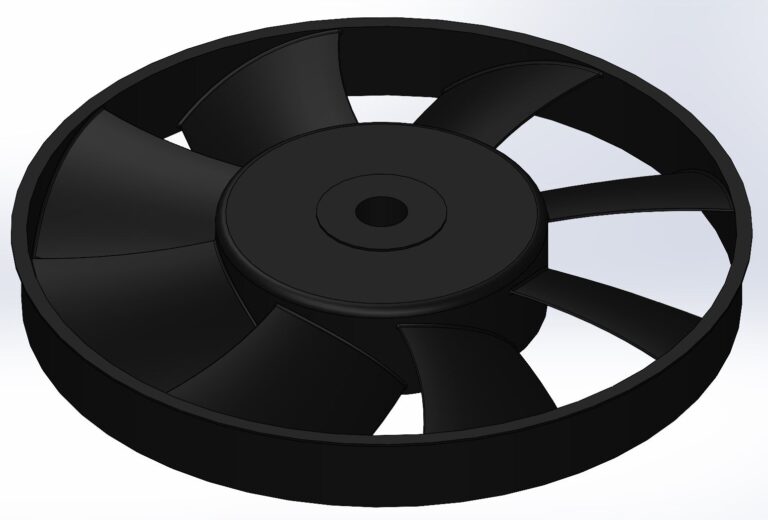

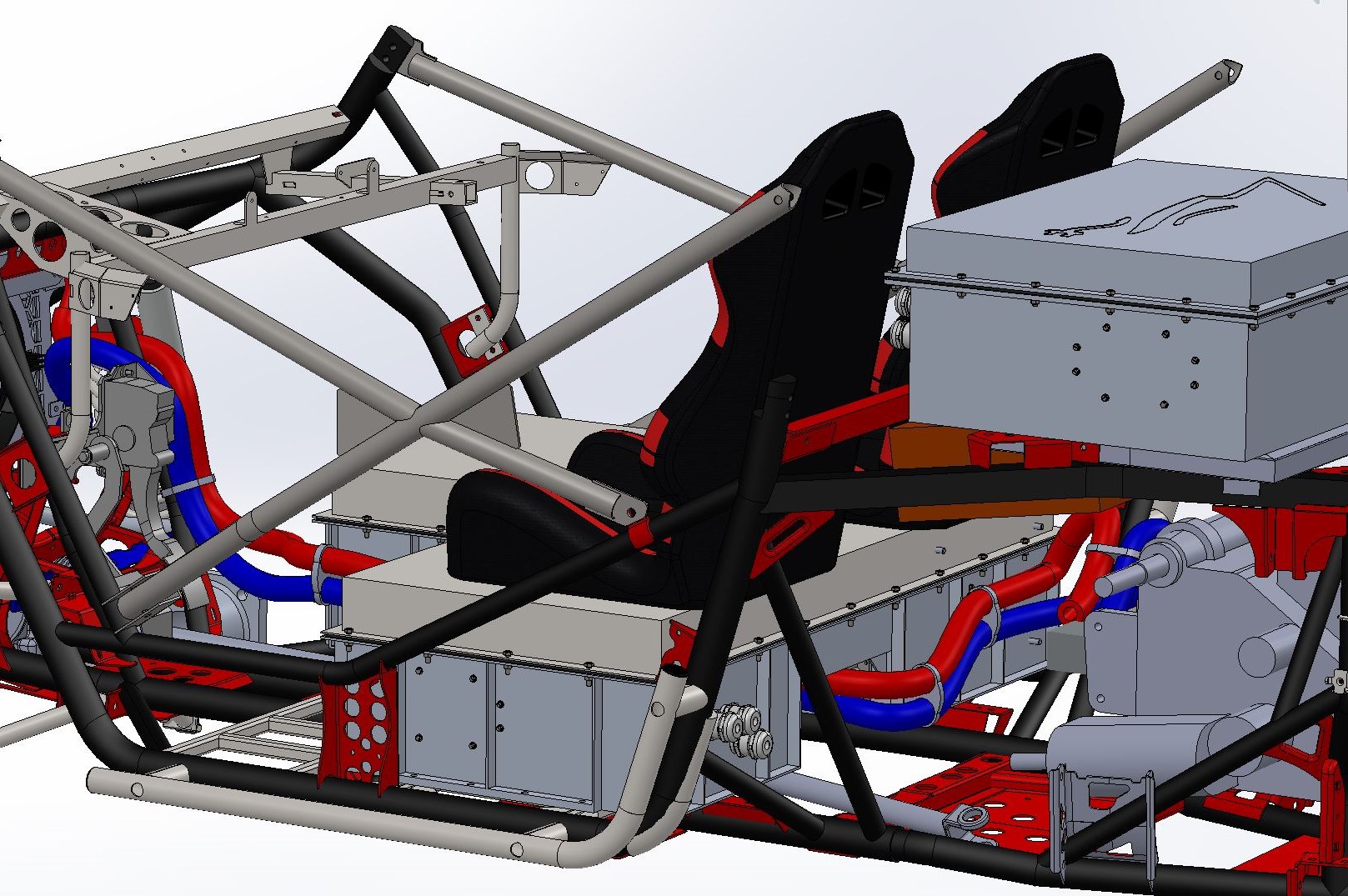

Member Of A Scientific Group

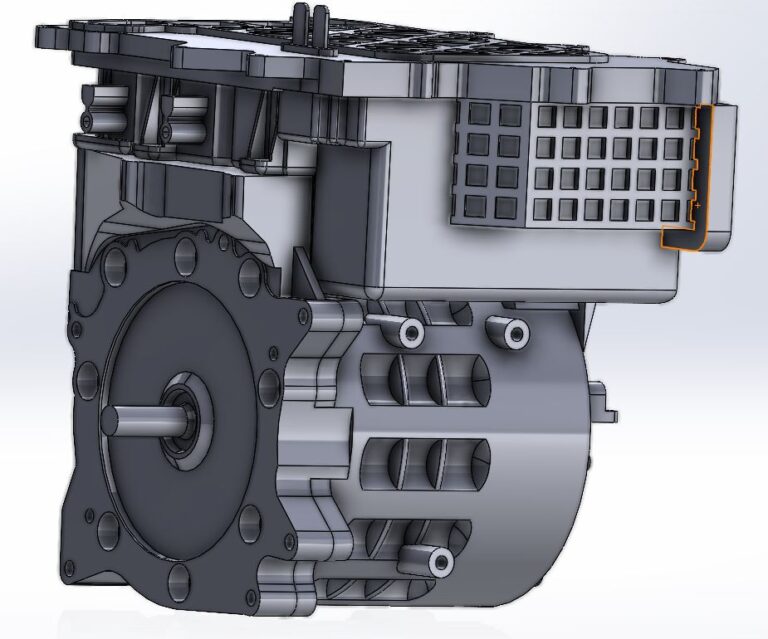

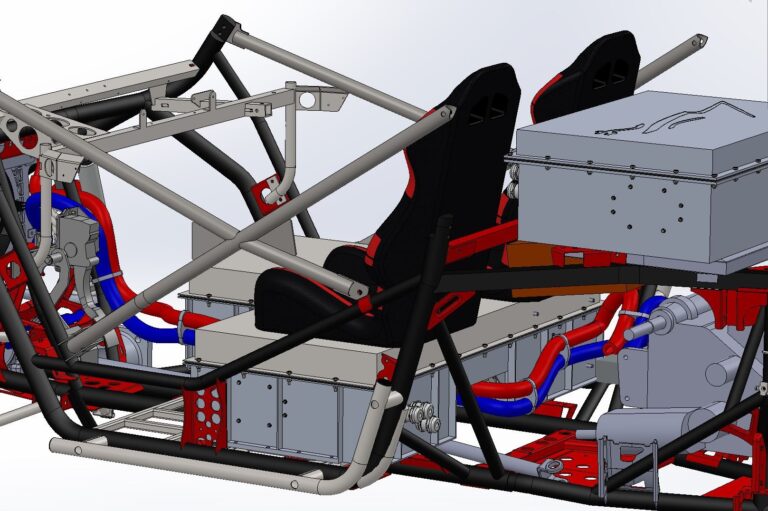

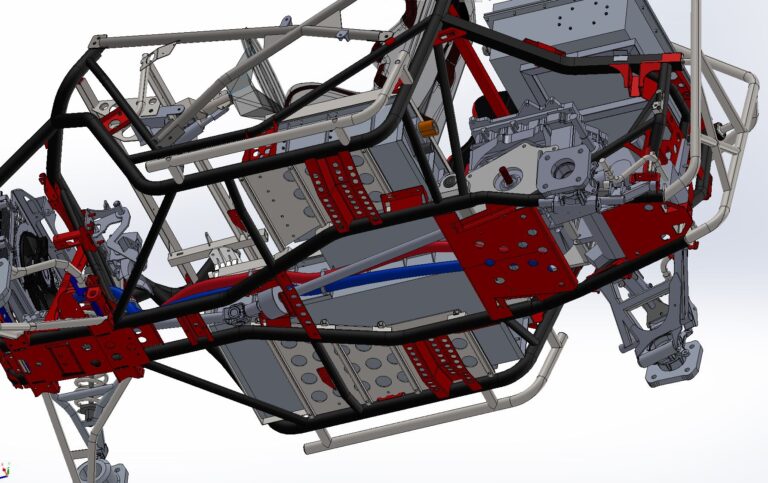

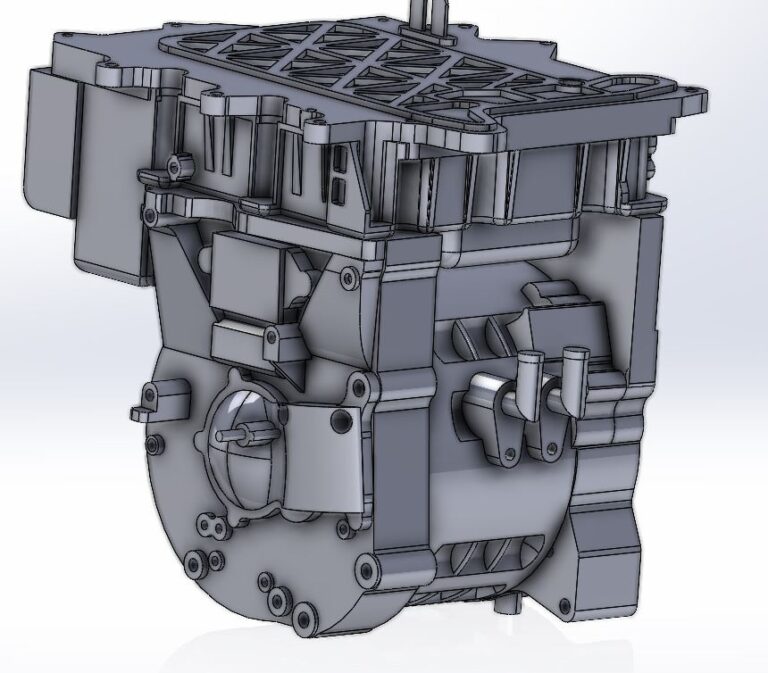

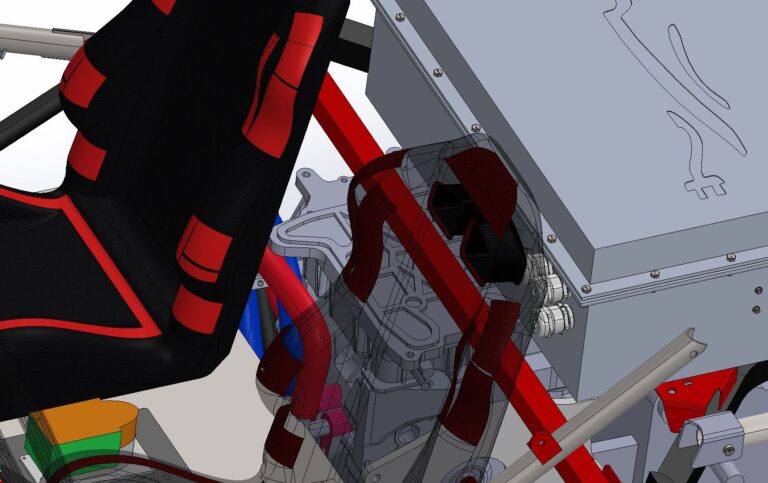

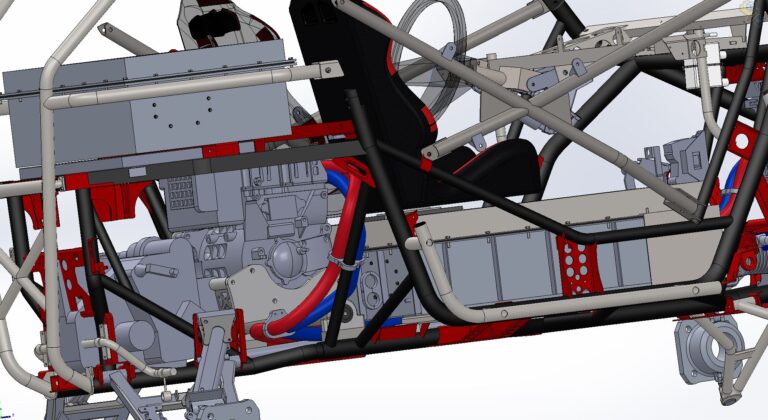

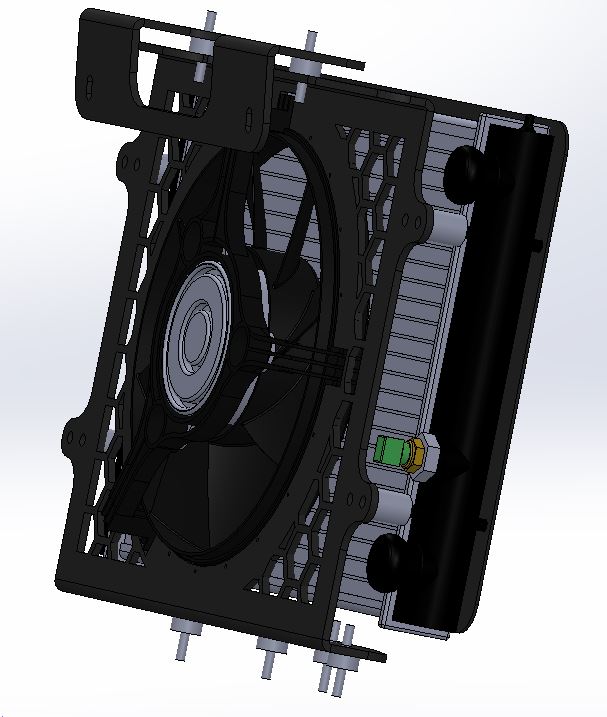

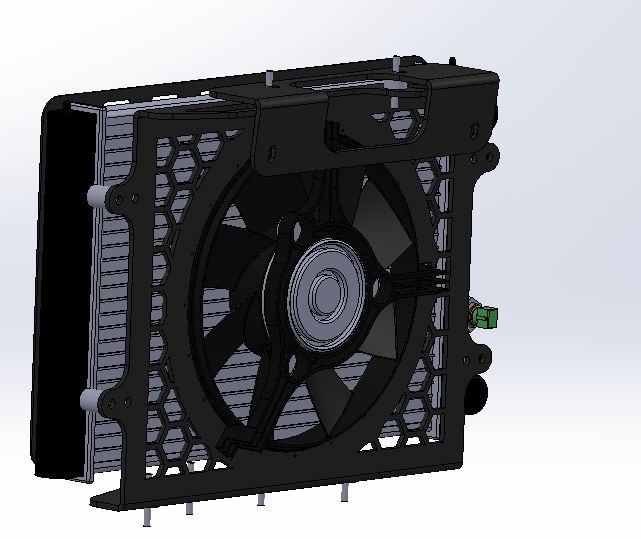

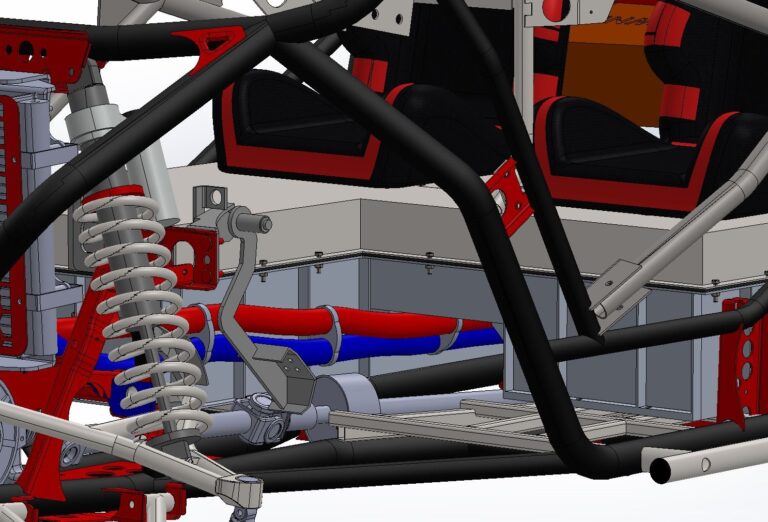

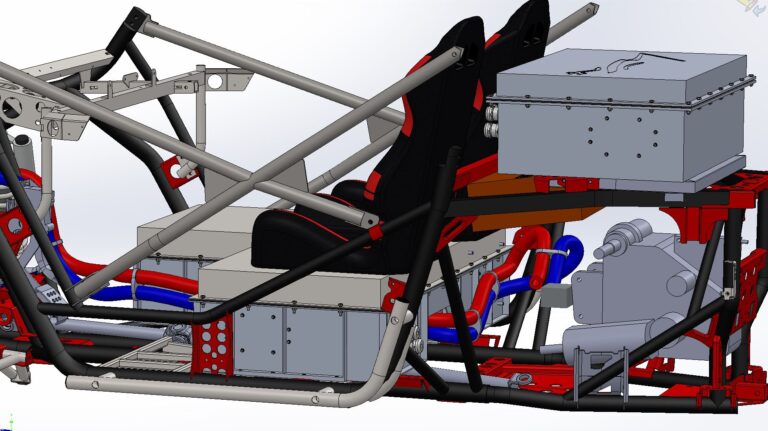

In 2021/2022 I was a member of a scientific group at Wroclaw University called LEM Wroclaw Motorsport. One of my tasks there was to design 3d models of different mechanical parts and manage large assemblies of different components. I was also involved in various projects in workshops, e.g. testing the cooling systems of a new electric buggy, evaluating how parts that I designed in CAD software were performing in real environments, and testing new ways of casting aluminum parts using 3d printed models (Lost PLA Casting).

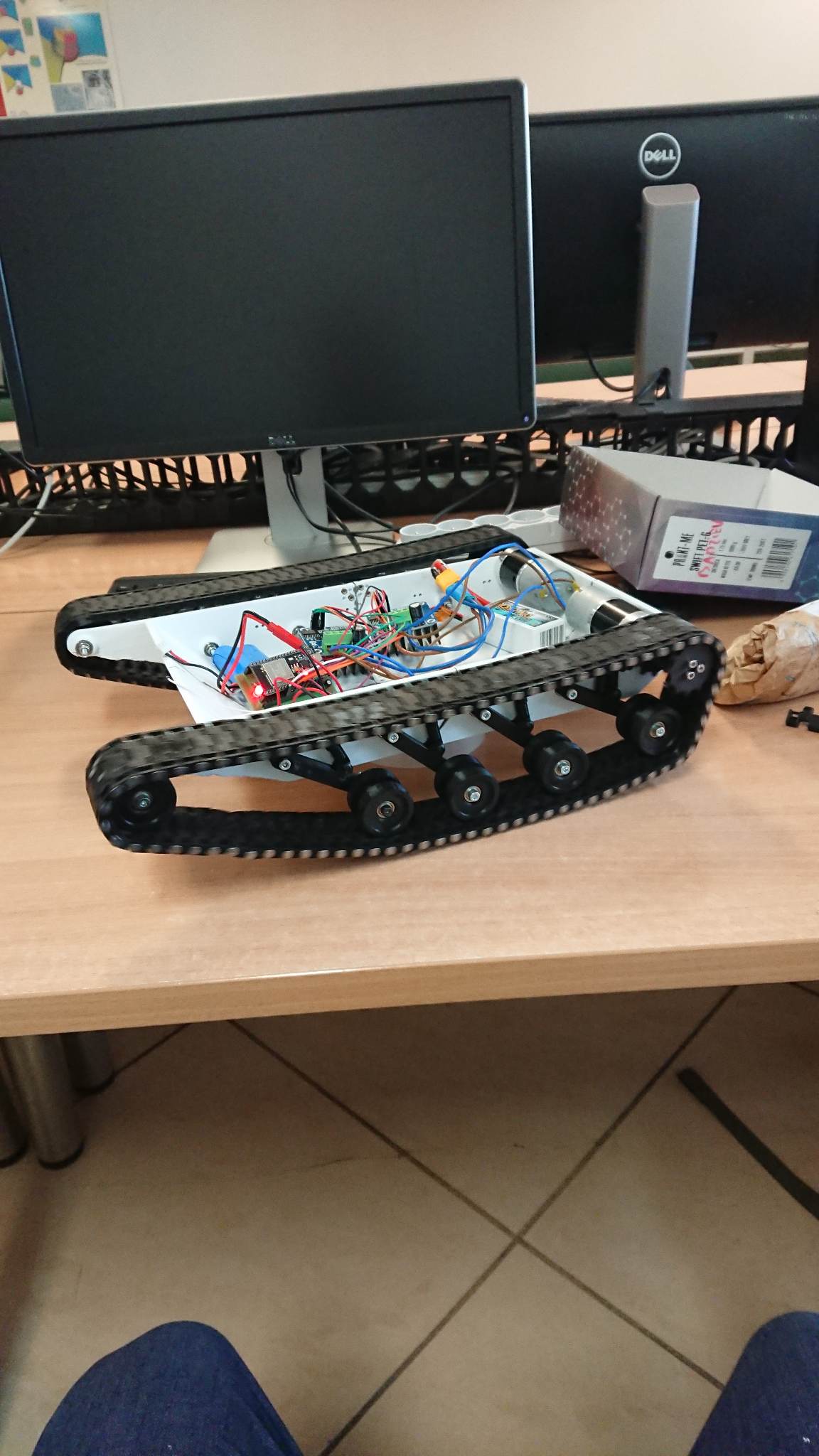

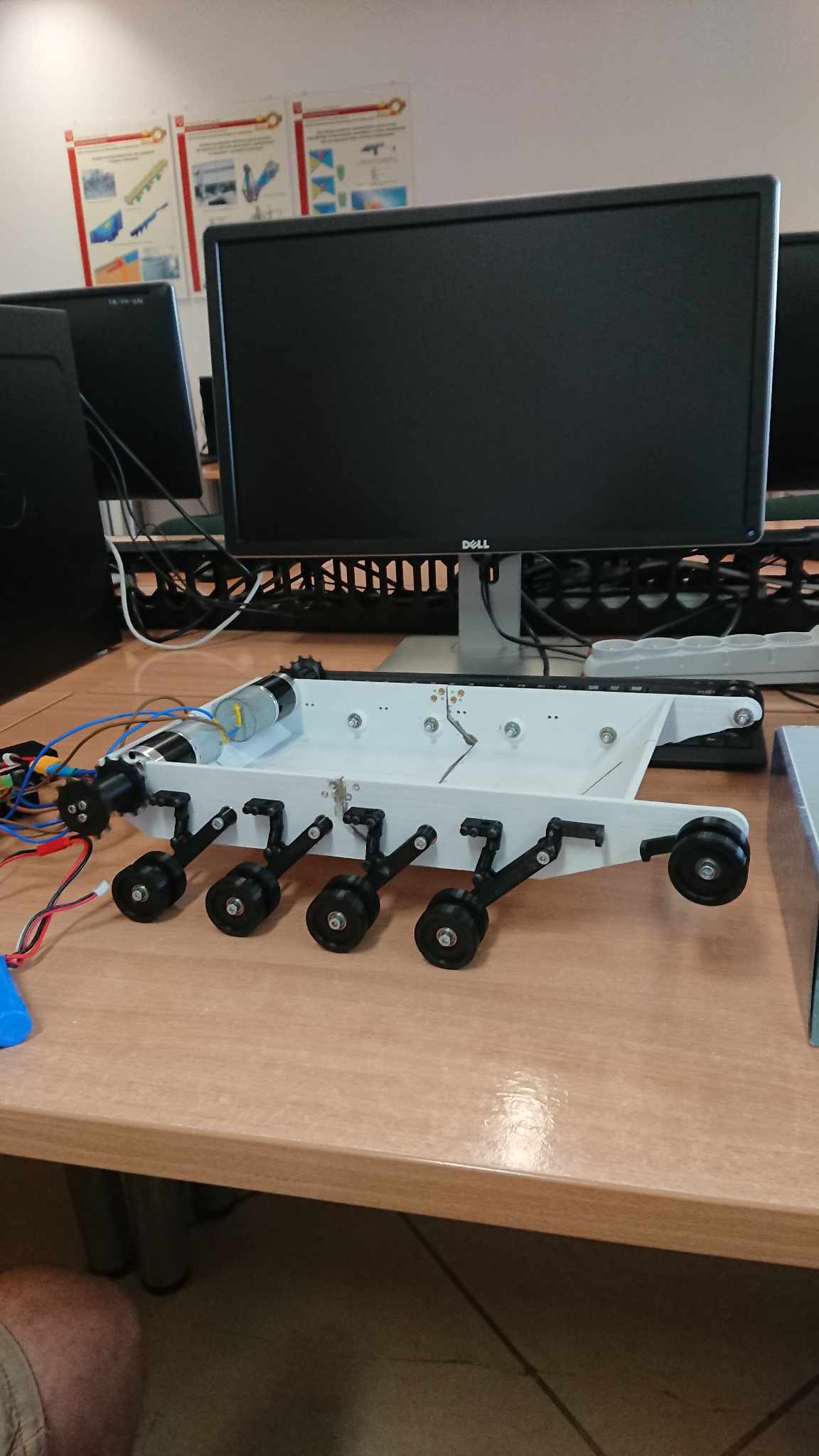

RC Tank

As part of final-year university project, me and one of my friends created an RC tank with special suspension and custom electronics, fully 3d printed (main body, wheels, rollers as well as tracks). Due to the size limits of our 3d printer, we had to print the main body in 2 sections that were later glued together.

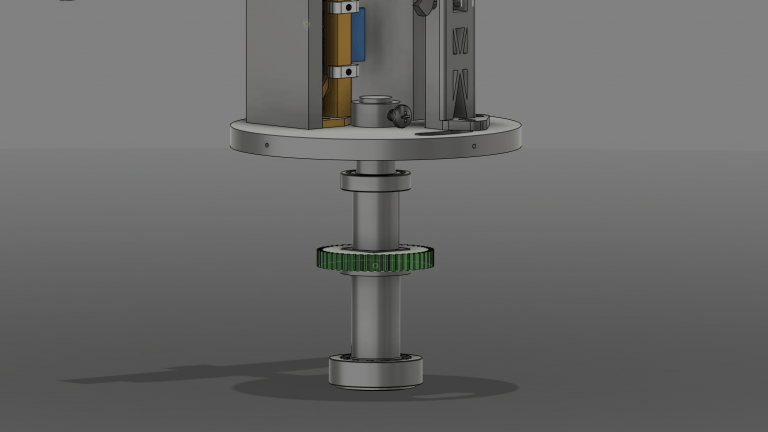

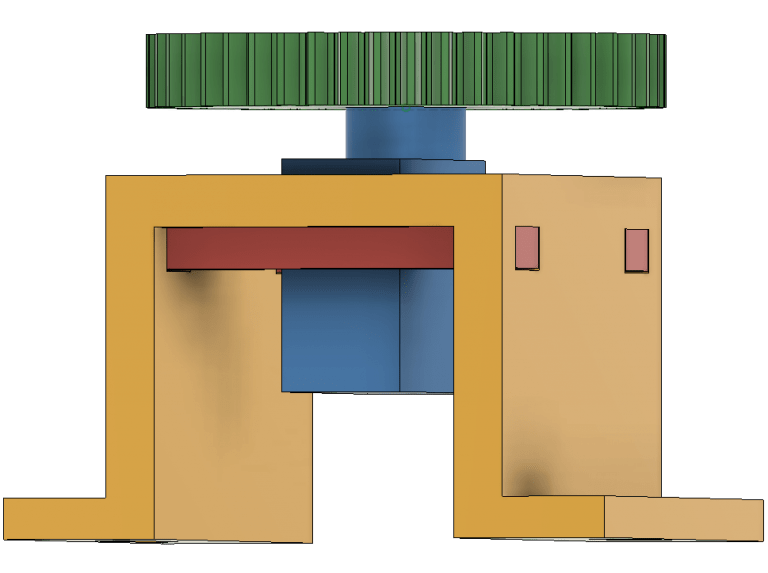

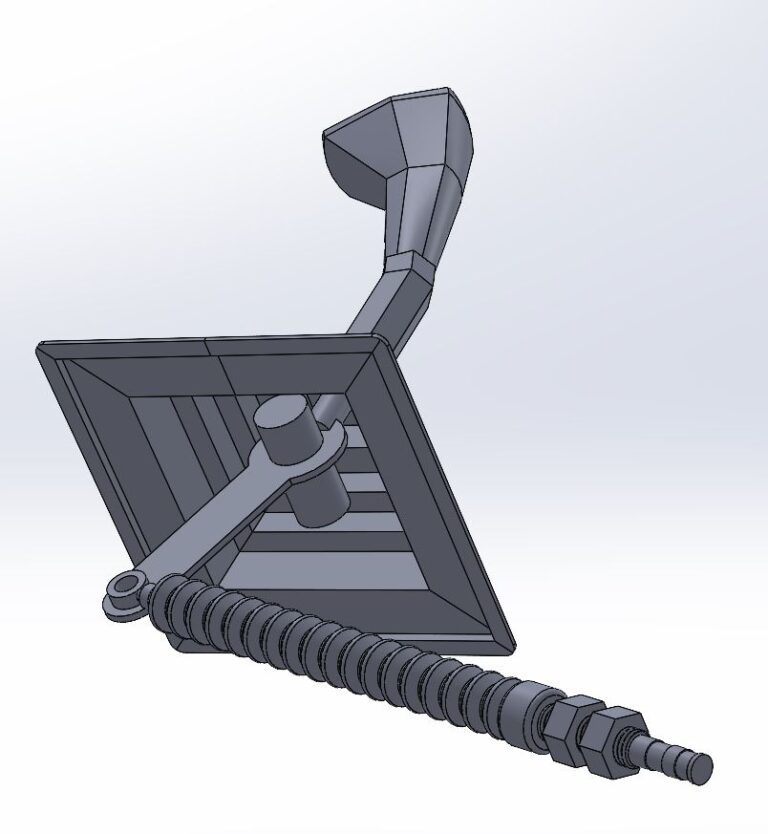

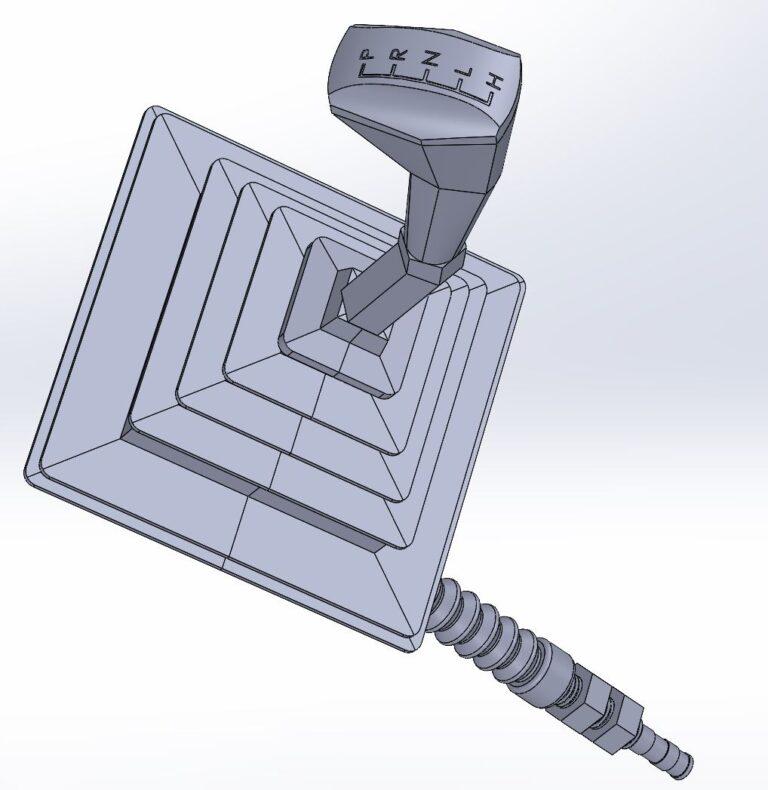

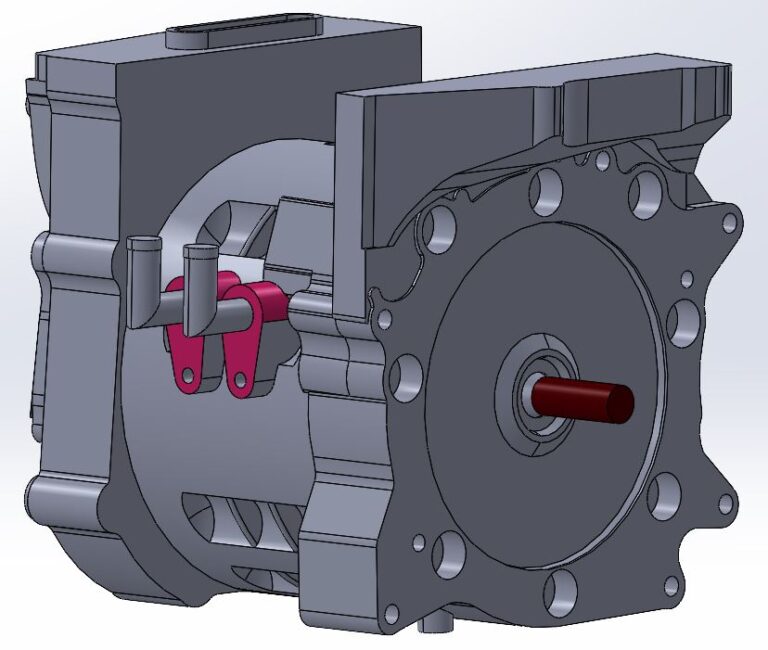

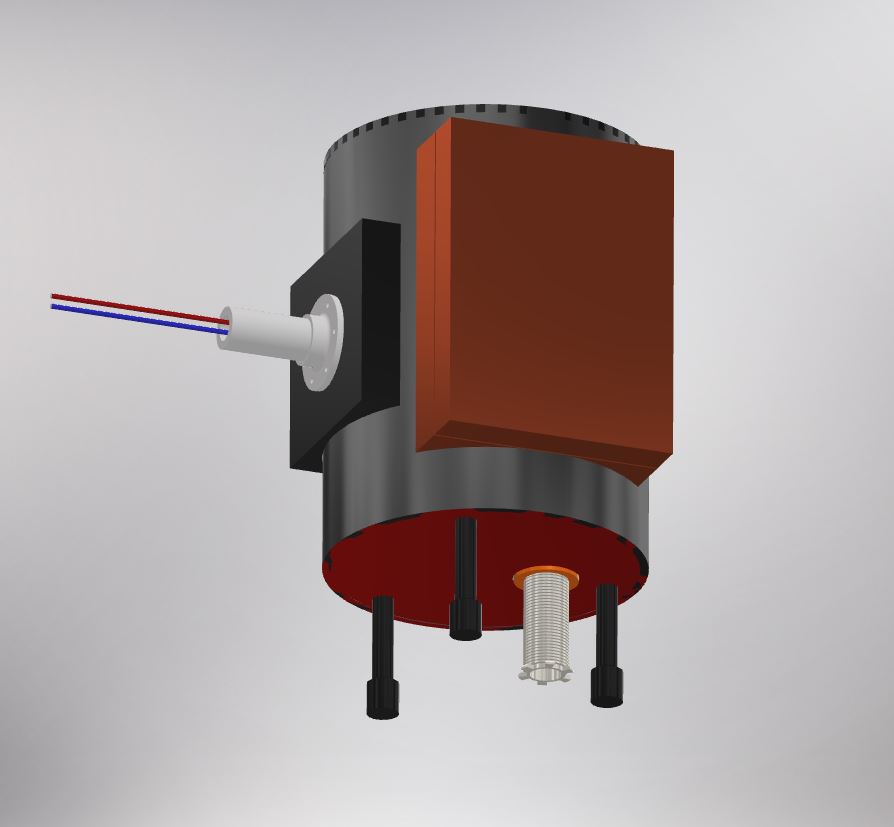

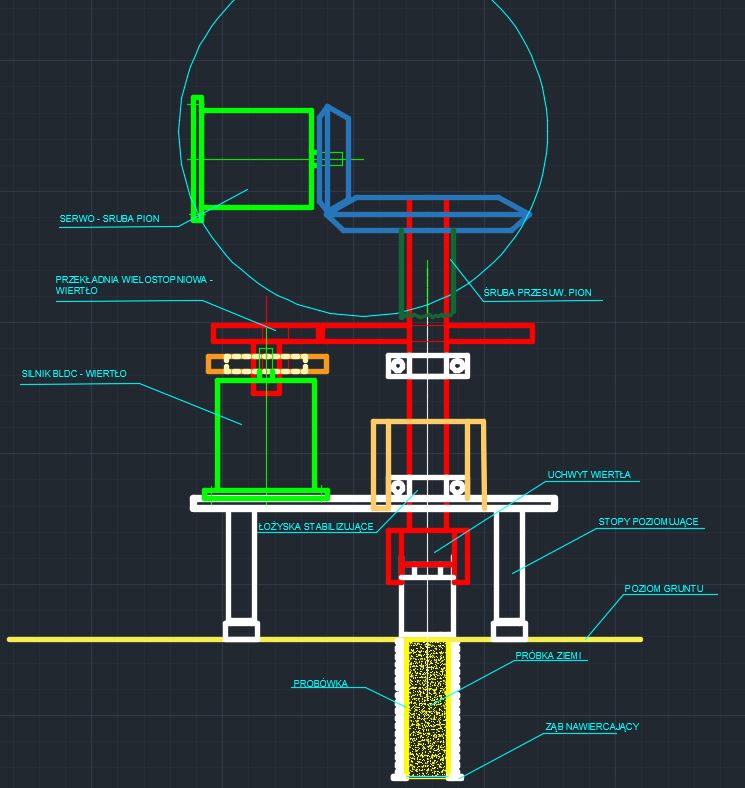

Soil Extractor

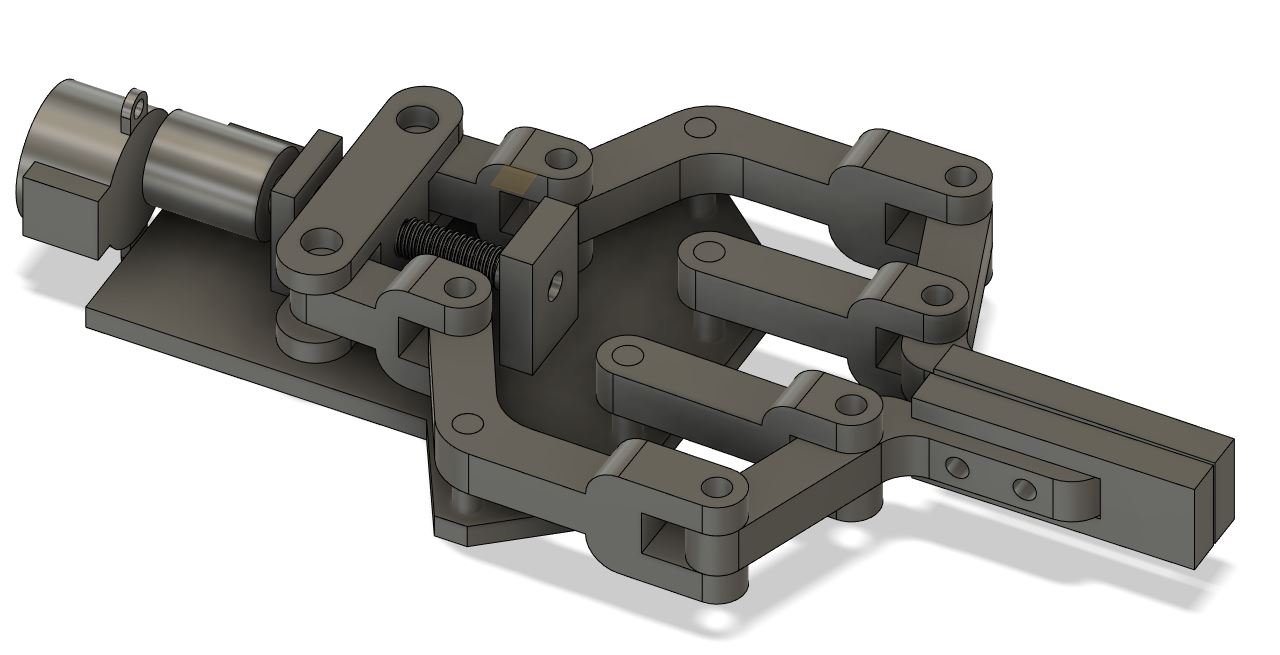

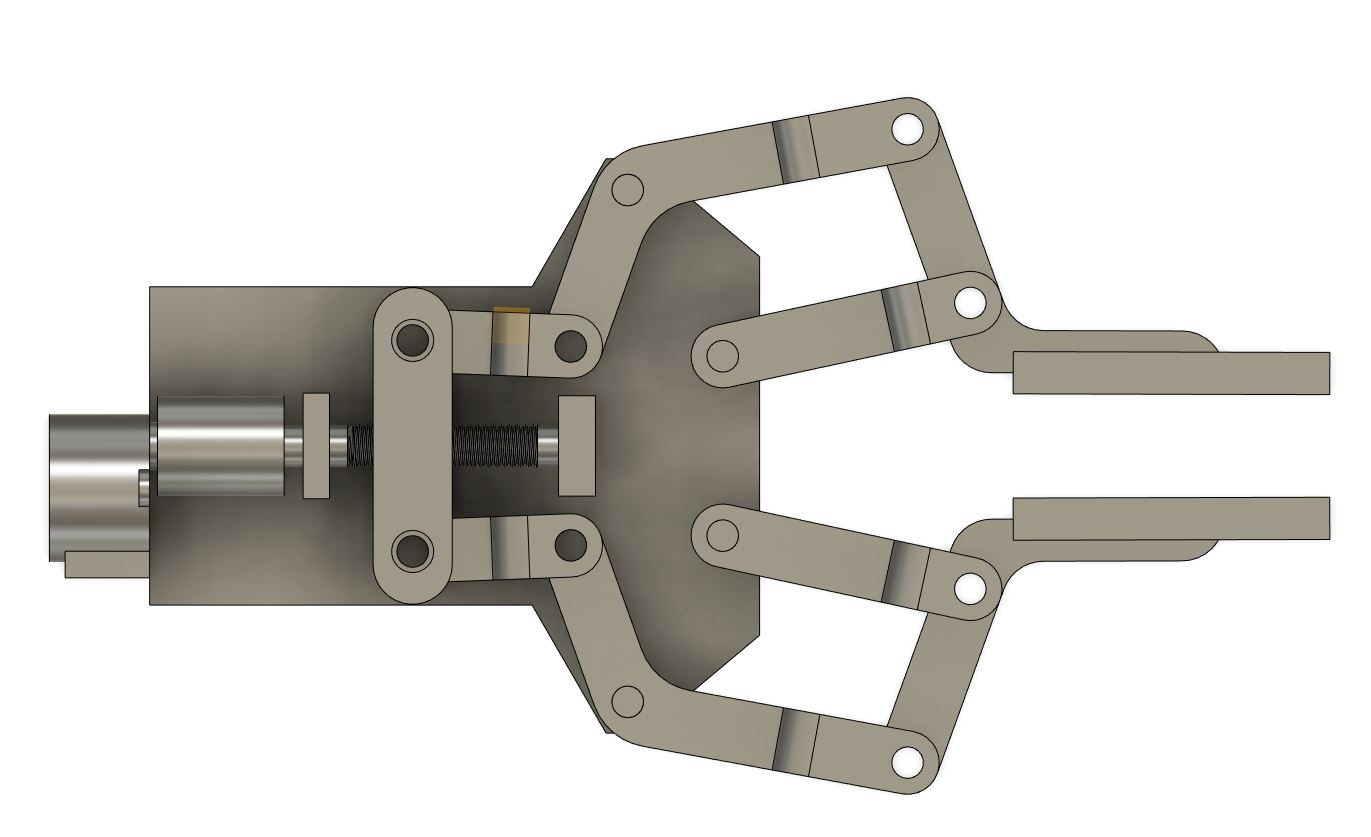

As part of my deep passion for space exploration and space rovers, I started to design a cylindrical head with a special unit that would extract a soil samples for further analysis. This device would be later on attached to a rover’s arm. In addition to that, I created a first version of a new robot gripper that could hold various tools and use them on special missions on different planets.

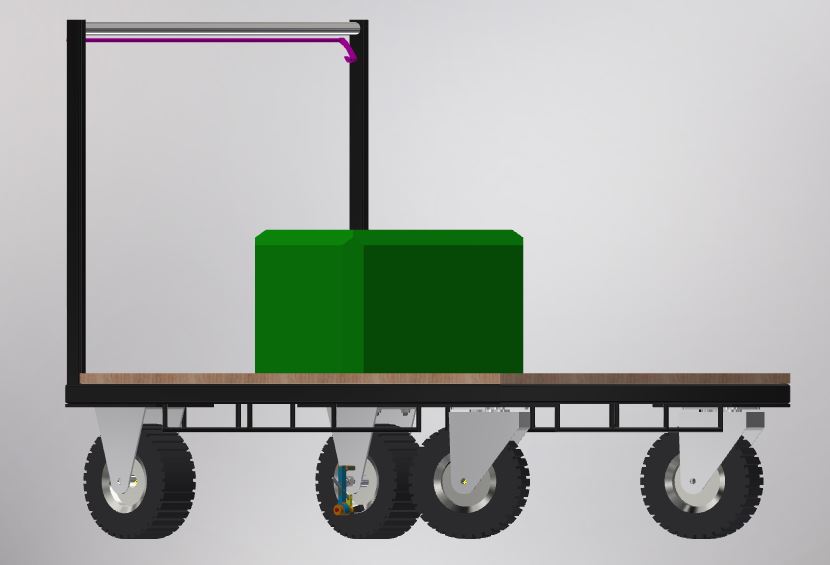

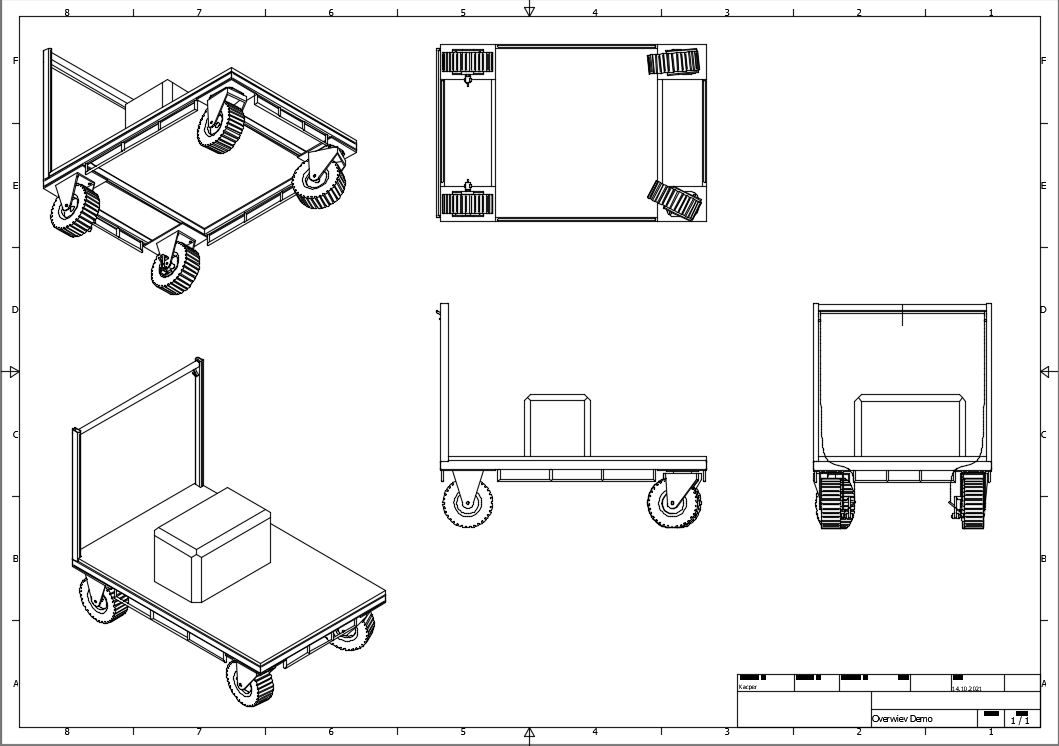

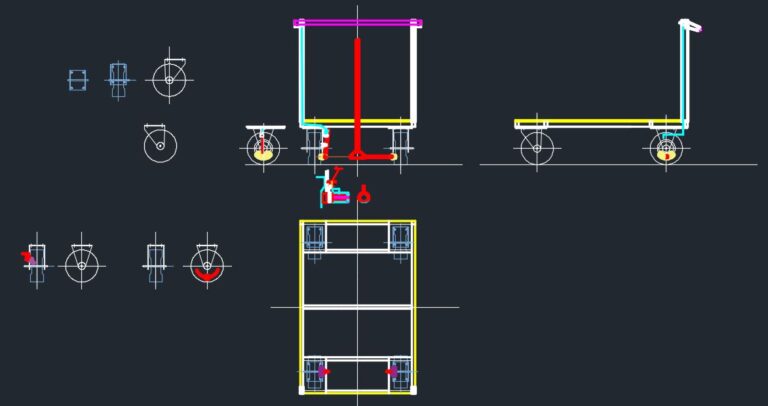

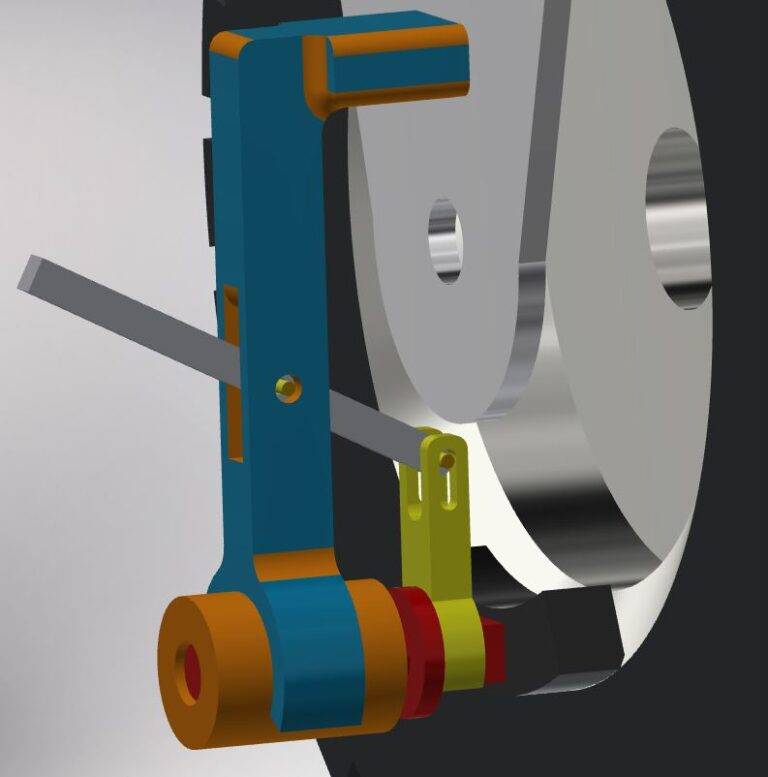

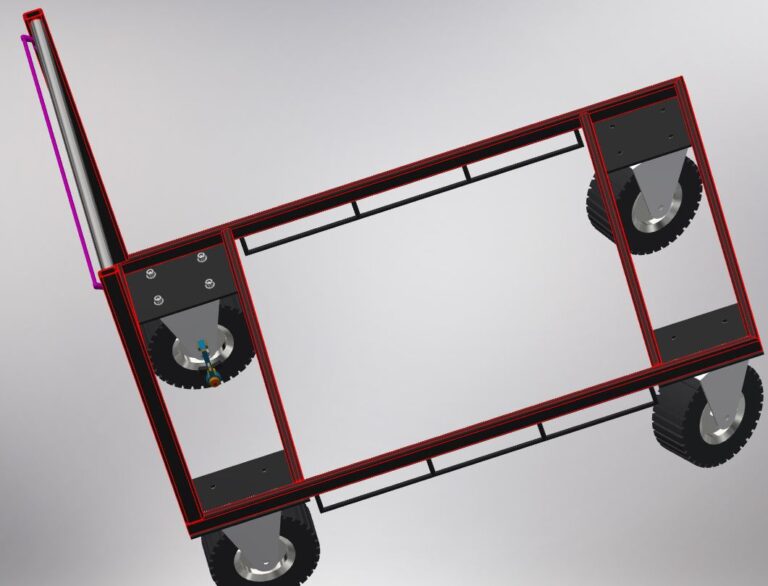

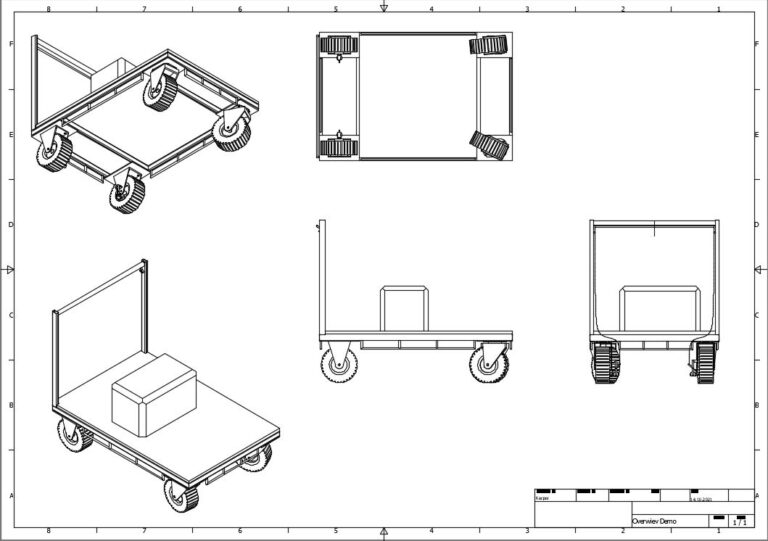

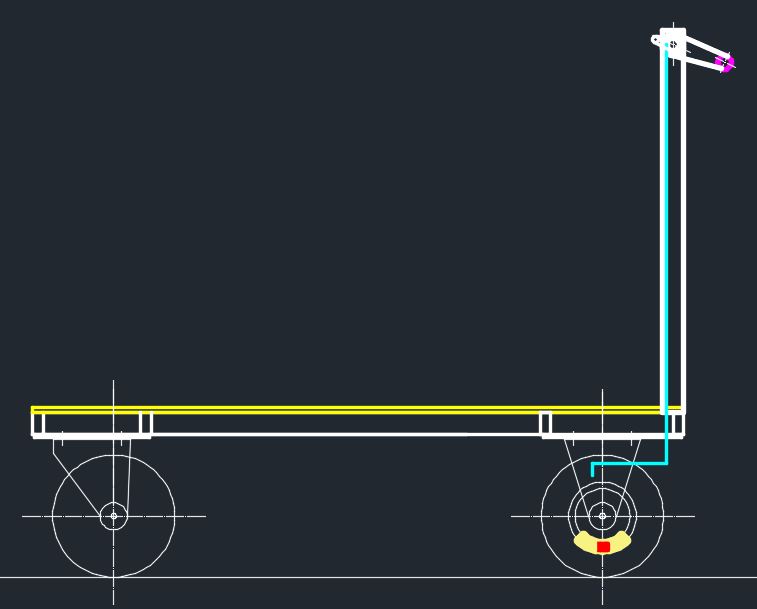

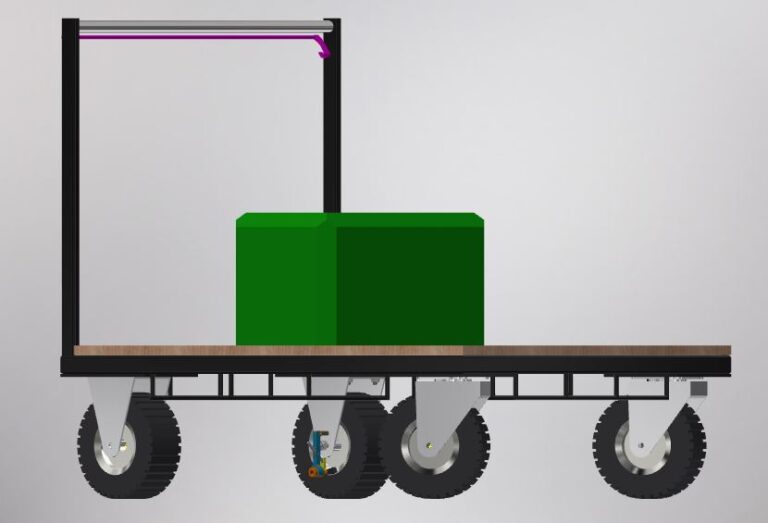

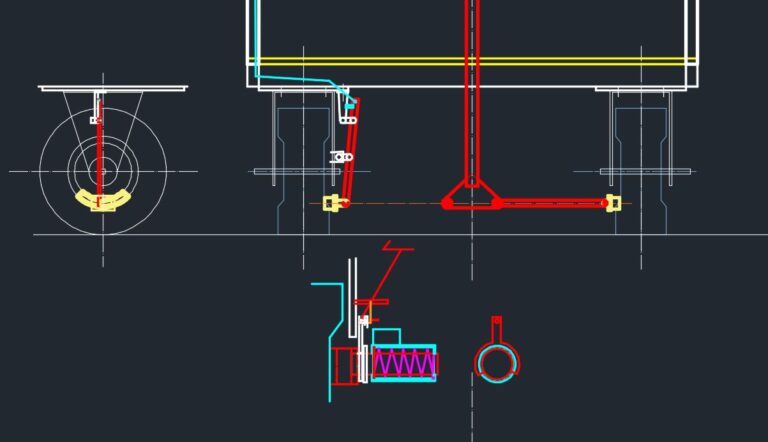

Hand Cart with safety brakes